What is the production process for fuse cast AZS blocks?

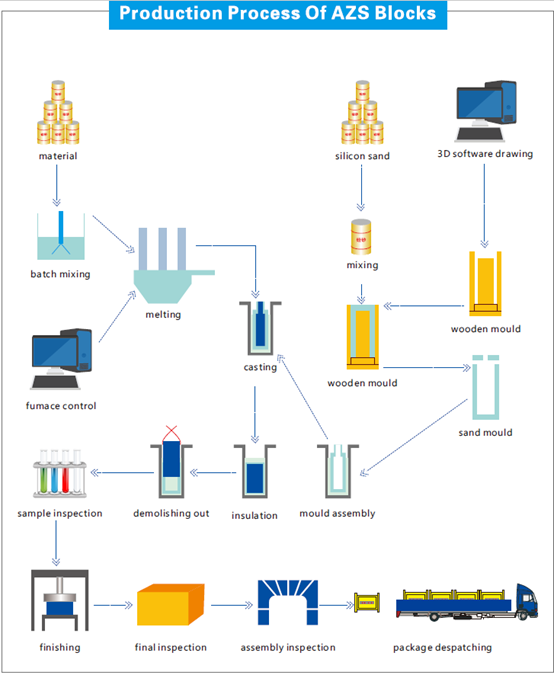

The production process for fuse cast AZS blocks is as follows:

1. Preparation of fused zirconium corundum raw materials.

We SNR import high quality zircon sand from Australian company ILUKA to get a more stable quality performance. Mix them together with alumina powder (purchasing from CHINA ALUMINA GROUP) and silica material in a proper ratio.

2. Fusing the raw material

Add the raw material into the automatically controlled electric arc furnace and melt it under optimal conditions. The melt temperature of the batch material melted in a single-phase or three-phase electric arc furnace should be moderate. If the temperature is low, a highly uniform melt cannot be produced, and the casting will easily form a porous body, resulting in pores and cracks in the melted and cast product, and the shrinkage will also increase accordingly. The key to the melting process is to maintain a stable melting temperature system and produce a melt with uniform chemical composition, low carbon content, a certain temperature and good casting properties.

.png)

3. Casting

The molten material is injected into a specially designed mold. We SNR use resin sand mold to make the cast with dense structure and good performance. When cast with appropriately superheated melt, the shrinkage holes of the cast zirconium corundum brick are concentrated, the thickness of the dense zone increases, and the density of the entire product also increases. However, when the degree of overheating is too high, although the melt density increases, it is easy to cause cracks and large shrinkage cavities in the product.

.png)

4. Annealing

The cast bricks are slowly cooled (annealed) so that the crystals of the zirconium corundum bricks grow and form the optimal structure. Usually, an insulating box filled with diatomite and other insulation materials is used for mold annealing, or an adjustable temperature resistance furnace or tunnel kiln is used for mold or demoulding annealing according to a certain temperature system. The initial annealing temperature and insulation conditions have a significant impact on the annealing effect.

5. Surface machining (processing)

Precision processing equipment is used to process the finished fused zirconium corundum bricks into precise sizes that meet the design requirements. Mechanical processing is also a means to improve the quality of fused bricks and extend their service life.

6. Inspection

Each fused zirconium corundum brick undergoes strict appearance inspection in accordance with contract standards.

7. Physical and chemical analysis

For contract regulated AZS blocks, we make the physical and chemical analysis on them.

8. Pre-assembling

Pre-assemble the fused zirconium corundum bricks used in key parts according to the drawings.

9. Packing

We use wooden pallet and box to pack the fused AZS blocks to fit for long journey transportation.

.png)

The use of fuse cast corundum bricks (fused high alumina) and cast zirconium corundum blocks (fused AZS) can extend the service life of flat glass melting furnaces to 5 to 7 years.

If any queries for refractory bricks, please feel free to contact with us. Whatsapp: +86-18203976036, davis@snrefractory.com