|

Item |

AZS41 |

|

|

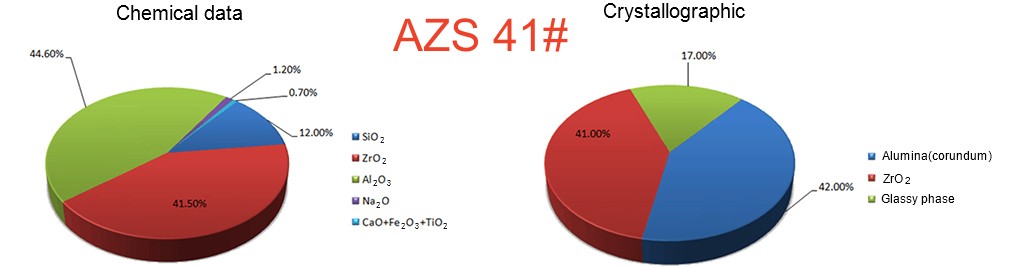

Chemical |

Al2O3 |

≥45.00 |

|

ZrO2 |

≥40.50 |

|

|

SiO2 |

≤12.50 |

|

|

Na2O+K2O |

≤1.30 |

|

|

Volume density g/cm3 |

≥4.00 |

|

|

Apparent Porosity % |

≤1.2 |

|

|

Cold Crushing Strength Mpa |

≥200 |

|

|

Exudation Temperature of Glass Phase |

≥1410 |

|

|

Bubble Separation Ratio(1300℃×10h) |

≤1.0 |

|

|

Anti-corrosion rate of glass liquid |

≤1.2 |

|

|

|

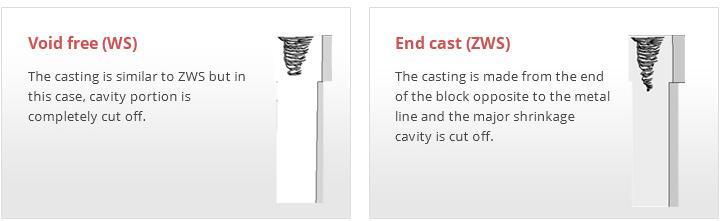

PT(RN RC N) |

≥3.80 |

|

ZWS(RR EVF EC ENC) |

≥3.95 |

|

|

QX(RO) |

≥3.90 |

|

|

WS( RT VF EPIC FVP DCL) |

≥3.98 |

|

Fused cast AZS 41 block contains more uniformly distributed zirconium oxide crystals, which combine with co-crystals of silicon oxide and alumina to form a dense microstructure, resulting in effective resistance to the erosion of glass liquids with minimal contamination of the glass liquids. Fused cast AZS 41 blocks have high-temperature stability and are resistant to scouring.

Barrier block

Weir is the key area where the glass liquid flows and changes in the furnace, fused cast AZS 41 blocks have high resistance to erosion of glass liquid, low pollution characteristics, good thermal stability and mechanical strength as well as the ability to adapt to the specific working environment of the weir, which makes them an ideal choice for the key part of the glass furnace.

Doghouse

Fused cast AZS 41 block has very high resistance to erosion by liquid glass and low contamination properties, which can effectively protect this vulnerable area and extend the service life of the furnace. Specifically, fused cast AZS 41 blocks contain more uniformly distributed zirconia crystals, which provide excellent erosion resistance and shallow contamination of the glass liquid, making them particularly suitable for use in glass furnaces in critical areas such as the doghouse corner, which are characterized by high temperatures .

Henan SNR Refractory Co., Ltd (SNR) has been committed to the development of high-quality fused cast AZS blocks.If you have any needs, please contact us.