What are Fused Cast AZS Refractory Blocks?

Fused cast AZS (Alumina-Zirconia-Silica) refractory blocks also named as eletrocast AZS refractory blocks are the core part of glass furnaces. It is made from melting raw materials of zircon sand, alumina powder and others . Known for their exceptional corrosion and erosion resistance to molten glass, fused cast AZS refractory blocks are used in different areas of glass furances like glass furnace melting tank,glass furnace throat ,working end,breastwall and superstructurer,regenerator and etc.

Fused Cast AZS Blocks Quality Grades and Specifications

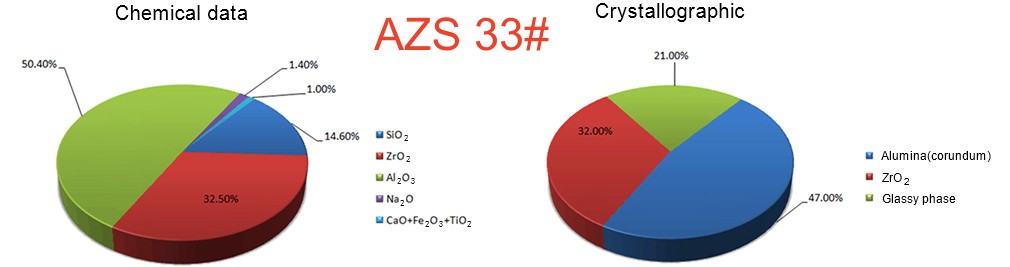

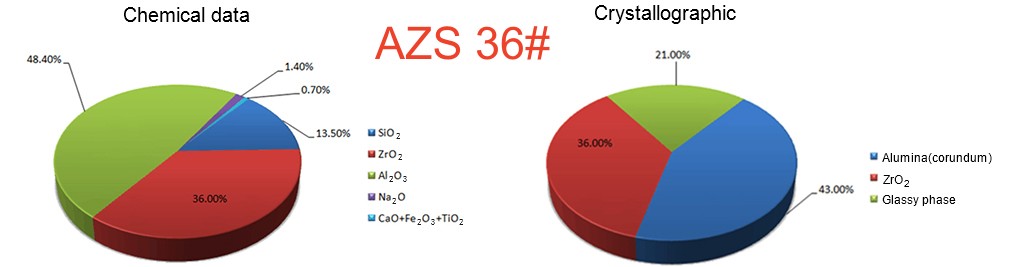

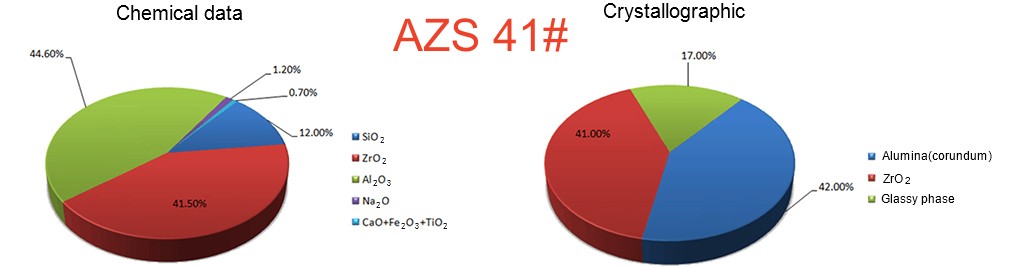

There are three grades for fused cast AZS blocks: AZS 33#,AZS 36# and AZS 41#.

Different grades AZS blocks will be used in different parts of glass furnace. For example, for the thorat part of glass furnace, AZS 41# blocks must be used.

AZS 33# Block

AZS 36# Block

AZS 41#Block

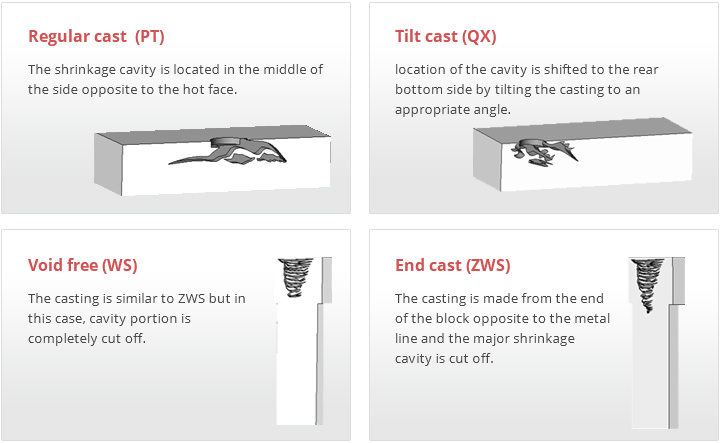

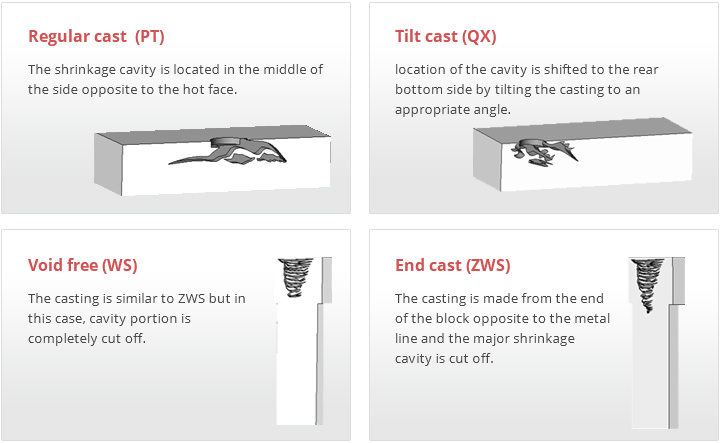

For each grade AZS refractory block, there will be different casting quality: normal casting, end cut casting and void free casting.

AZS 33#PT(normal casting) blocks are usually used in the superstructurer part of the furnace

AZS 33#WS(Void Free casting)blocks are used as paving tiles or tank sidewall blocks

AZS 36#ZWS( End cut casting) blocks are used as tank sidewall blocks

AZS 41#WS(Void Free casting) blocks are used as corner blocks and thorat part blocks

If you want to get more details and specification of each quality fused cast AZS block, please send us Email: info@snrefractory.com

How to Produce Fused Cast AZS Refractory Blocks?

1. Raw Material

The production of fused cast AZS refractory blocks begins with carefully selected high-purity raw materials: Zircon Sand, Alumina Powder, Desilicated Zirconia(ZrO2>99%). SNR only use Iluka Brand Zircon Sand from Austrilia.

2.Batch Mixing

The raw materials are precisely weighed and mixed in a controlled environment to ensure homogeneity. The mixing process aims to achieve a consistent distribution of all material, which directly influences the final properties of the fused cast AZS blocks.

3.Melting and Casting

The well-mixed raw materials are then fed into a high-temperature arch electric furnace. The melting process involves subjecting the batch material to intense heat, typically exceeding 2,400 degrees Celsius. To remove the dust, Oxygen will be used during the melting process. SNR has automatic melting technology and equipment for melting control, and oxygen will be automatially blowed into the molten material during melting. At such high temperatures, the raw materials undergo a fusion reaction, forming a molten liquid. After the raw materials are well melt, the molten liquid is carefully casted into pre-designed molds according to the size of the fused cast AZS blocks, which are made from refractory materials capable of withstanding the extreme conditions of the casting process.

4. Annealing

Before casting, the molds will be put into a steel plate annealing box filled with annealing material. After casting process, the annealing box will be moved to an area for natural annealing of 10-14 days. Annealing process will reduce thermal stress and prevent cracking or other defects on the AZS blocks. And the cooling rate is carefully regulated to achieve optimal microstructure and desirable crystal formation within the fused cast AZS blocks.

5. Cutting and Grinding

After annealing, the fused cast AZS blocks will be demolded and sent for maching process. SNR has good cutting and grinding machines to make sure the accurate dimensions of each individual fused cast AZS blocks.

6. Assembling

Assembling is also very important to the lifetime of glass furnace. The whole fused cast AZS Refractory blocks assmebling dimensions tolerance must be within the requirement and the joints between blocks must be within 0.5 mm, maximumly 1mm for some parts. SNR will use laser to make sure of the accuracy and flatness of all AZS blocks assembling and will make strict inspection.

As a professinal fused cast AZS refractory blocks manufacturer, Henan SNR refractory Co.,ltd will always keep improving to provide the customers with better products and service. If any question or demand of fused cast AZS blocks, please feel free to contact us: info@snrefractory.com

.jpg)