.jpg)

|

Item |

AZS33 |

|

|

Chemical |

Al2O3 |

≥50.00 |

|

ZrO2 |

≥32.50 |

|

|

SiO2 |

≤15.00 |

|

|

Na2O+K2O |

≤1.30 |

|

|

Volume density g/cm3 |

≥3.75 |

|

|

Apparent Porosity % |

≤1.2 |

|

|

Cold Crushing Strength Mpa |

≥200 |

|

|

Exudation Temperature of Glass Phase |

≥1400 |

|

|

Bubble Separation Ratio(1300℃×10h) |

≤1.2 |

|

|

Anti-corrosion rate of glass liquid |

≤1.4 |

|

|

|

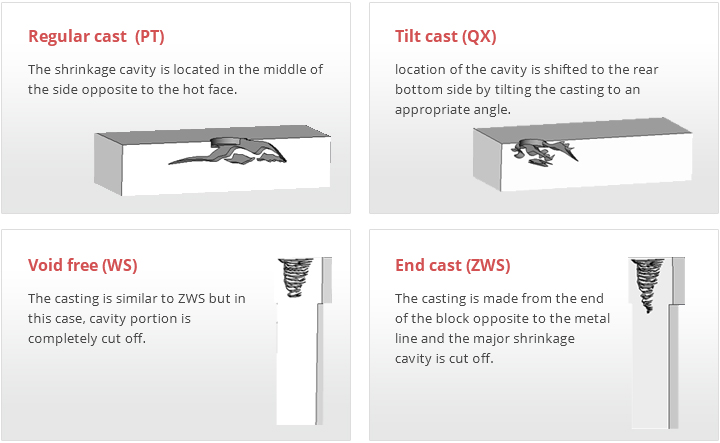

PT(RN RC N) |

≥3.45 |

|

ZWS(RR EVF EC ENC) |

≥3.65 |

|

|

QX(RO) |

≥3.65 |

|

|

WS( RT VF EPIC FVP DCL) |

≥3.75 |

|

Fused cast AZS 33 blocks ensure the stability and purity of the superstructure, reducing the generation and spread of contaminants, while having high structural strength to maintain the integrity and stability of the superstructure. The superstructure of a glass furnace may consist of different parts and shapes. Fused cast AZS 33 blocks can be customized to meet the requirements of different structures and shapes.

Feeder channel

Fused cast AZS 33 blocks have a dense microstructure, and strong erosion resistance, to ensure the stability and durability of the feeder channel, but also in the high-temperature environment to maintain stable physical and chemical properties, it is not easy to deformation or rupture, to ensure that the normal operation of the channel in high-temperature conditions.

Fused cast AZS 33 blocks have high abrasion resistance, which can resist the glass liquid's scouring and abrasion and extend the feeder channels'service life. Feeder channels may have different shapes and sizes and can be customized to meet the design requirements of other channels.

Henan SNR Refractory Co., Ltd (SNR)has been committed to the development of high-quality fused cast AZS blocks.If you have any needs, please contact us.