SNR Brand Fused Cast AZS 36# Blocks

ZrO2>35.5%

Longer Working Lifetime in Glass Furnace

Better performance of anti-corrosion for glass liquid

Better ability of withstanding aggressive enviroment in glass furance

Widely used in melting tank sidewall, throat of glass furnace

What are Fused Cast AZS 36# Refractory Blocks?

|

Item |

AZS36 |

|

|

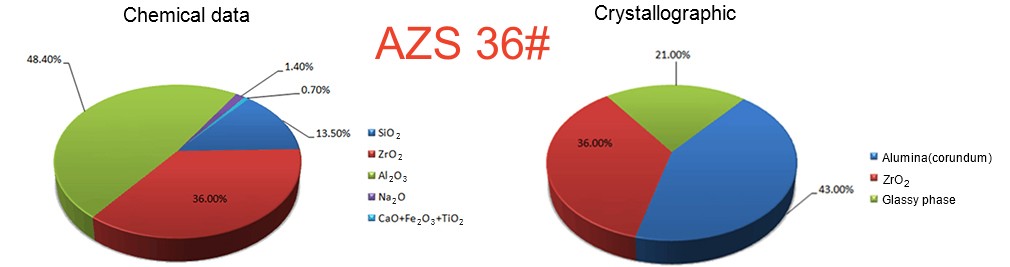

Chemical |

Al2O3 |

≥49.00 |

|

ZrO2 |

≥35.50 |

|

|

SiO2 |

≤13.50 |

|

|

Na2O+K2O |

≤1.35 |

|

|

Volume density g/cm3 |

≥3.85 |

|

|

Apparent Porosity % |

≤1.0 |

|

|

Cold Crushing Strength Mpa |

≥200 |

|

|

Exudation Temperature of Glass Phase |

≥1400 |

|

|

Bubble Separation Ratio(1300℃×10h) |

≤1.0 |

|

|

Anti-corrosion rate of glass liquid |

≤1.3 |

|

|

|

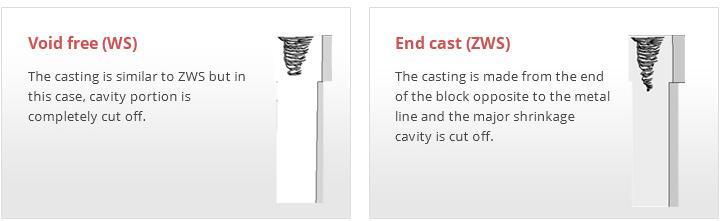

PT(RN RC N) |

≥3.55 |

|

ZWS(RR EVF EC ENC) |

≥3.80 |

|

|

QX(RO) |

≥3.75 |

|

|

WS( RT VF EPIC FVP DCL) |

≥3.85 |

|

Barrier wall

Fused cast AZS 36 blocks are the ideal choice for the glass furnace part due to their high resistance to glass liquid erosion, good thermal stability, and mechanical strength, as well as their ability to adapt to the specific working environment of furnace canopies.These performance characteristics enable fused cast AZS 36 blocks to maintain stability and durability in harsh working environments, providing a strong guarantee for the efficient operation of glass furnaces.

Henan SNR Refractory Co., Ltd (SNR) has been committed to the development of high-quality fused cast AZS blocks.If you have any needs, please contact us.