What is sintered AZS block and what is its application

Sintered zirconium corundum bricks (hereinafter referred to as AZS bricks) use alumina and zircon as raw materials. Generally, the ZrO2 content is controlled at 15% to 30%. The main crystal phase components are mullite, corundum and baddeleyite. Under certain conditions, the glass phase content can be lower than 5%, so the physical-chemical basis for the production of such products is mainly the solid-state reaction between Al2O3 and ZrSiO4.

1. Types of sintered AZS blocks.

There are three main types of products in this series:

① Reaction sintered AZS products are microstructures with uniform distribution of two phases composed of mullite and baddeleyite (including part of t-Zr02). This irreversible reaction is also called an in situ reaction. The reaction start temperature ranges from 1370 to 1420°C.

②Recombined AZS products are made by pulverizing, forming and sintering with electro-fused AZS as raw material.

③Containing zircon series products. This series of products belongs to the simplest process type in the generalized sintered AZS - using sintered or fused mullite or corundum or calcined bauxite coarse particles and zircon in any proportion, adding a small amount of bonded clay or other binders to be fired. become. The firing temperature determines the total decomposition of zircon particles, slight surface decomposition or no decomposition at all. There is no decomposition of zircon sintered at 1650°C, but the surface in contact with Al2O3 will decompose when it is less than 1500°C.

2. Production of Sintered Zirconia Corundum Bricks(Sintered AZS)

The key issues in the preparation process of sintered AZS products are:

① Ensure that ZrSiO4 reacts completely with Al2O3, sinters densely, and forms a uniform mullite-(corundum)-deleyite clinker, with a glass phase content of no more than 5%.

② The alumina + kaolin mixed in should conform to the composition of mullite.

③The particle size distribution of the product is reasonable to ensure the maximum bulk density.

④ The product is fully fired to obtain an ideal microstructure.

It is more difficult to produce high-quality sintered AZS products. In a sense, the strict requirements for controlling the process flow are no less than those for fused and cast products.

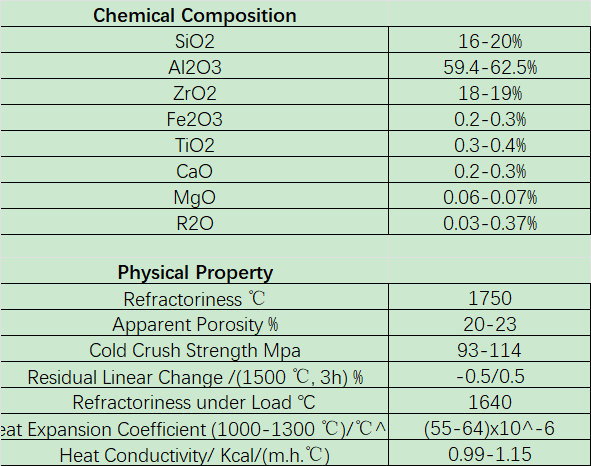

3. Sintered Zircon Corundum Block(Sintered AZS) Technical Specification

4. Sintered AZS Block Application

1.Glass Manufacturing: Sintered AZS blocks are extensively used in the glass industry, particularly in the construction of glass melting furnaces, regenerators, ports, checker bricks, and throat walls. The blocks have high resistance to thermal shock, corrosion, and erosion, making them ideal for containing and shaping molten glass.

2.Steel Industry: Sintered AZS blocks are also employed in the steel industry for applications such as steel ladle linings and tundish linings. They can withstand high temperatures and chemical reactions that occur during steel production, providing excellent resistance to corrosion and erosion.

3.Non-Ferrous Metal Industry: Sintered AZS blocks find application in the non-ferrous metal industry, specifically in the construction of smelting furnaces and crucibles for melting and refining materials like aluminum, copper, and zinc. The blocks' high refractoriness and resistance to chemical attack are advantageous in these environments.

4.Cement Industry: Sintered AZS blocks are used in the cement industry for lining kilns, preheaters, and cyclones. They provide superior resistance to alkali attacks and thermal stresses, ensuring prolonged service life in the harsh conditions of cement manufacturing.

5.Waste Incineration: Sintered AZS blocks are utilized in waste incineration plants for lining furnaces and other areas exposed to high temperatures and aggressive chemical environments. Their excellent resistance to thermal shock and chemical attack contributes to the durability and efficiency of waste treatment processes.

Where can you buy the high-quality sintered AZS bricks?

Zhengzhou SNR Refractory Co., Ltd (SNR) is a professional sintered refractories manufacturer in China for 30 years. We export refractories to 30 countries.

Whatsapp:0086-182 0397 6036,

Email:davis@snrefractory.com.