What is difference between sintered mullite brick and fused mullite brick?

Mullite is a refractory material mainly composed of 3Al2O3:2SiO2 crystal phase. Its chemical composition is AL2O3 content 71.8%, SiO2 content 28.2%. The mineral structure is orthorhombic; the crystal shape is columnar and needle-like; the bulk density is 2.5-3.03g/cm3, the Mohs hardness is 6~7, the melting point is 1870 degrees, and the thermal conductivity (1000°C) is 3.95W/(m·K) , the coefficient of linear expansion (20~1000°C) is 5.3×10-6.

There are many types of synthetic mullite. According to the synthesis method, there are sintered mullite and fused mullite: according to the chemical composition of the raw materials, there are low-alumina mullite, medium-alumina mullite, high-alumina mullite and zirconium mullite, etc.; if according to the type of raw materials used, there are all-natural synthetic mullite (rocky soil base), high-purity mullite, etc.

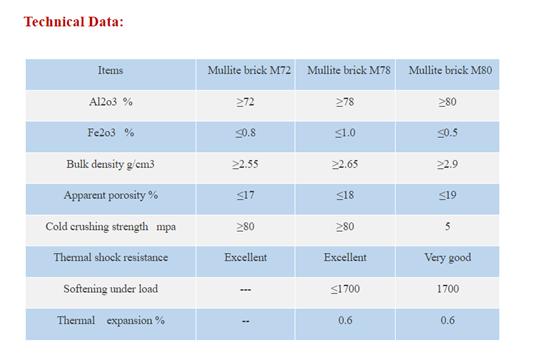

1. Sintered mullite brick

1.1 Sintered mullite production technology

The preparation of synthetic mullite raw materials can be divided into dry method and wet method. Burning kilns are mainly rotary kilns and tunnel kilns. The dry process is to put the batch materials into the ball mill or mixer and mix them together, and then burn them in a rotary kiln or tunnel kiln after being pressed or crushed. The wet process is to add the batch materials and water to the ball mill for wet mixing and grinding. The mud is press-filtered into a mud cake, which is extruded by a vacuum extrusion molding machine into a mud section or a mud cake, which is used for rotary kiln and road kiln respectively.

Compared with dry method, the quality of mullite waste produced by wet method is better, the structure uniformity is good, and the bulk density is high: tunnel kiln firing is beneficial to control the microstructure and crystal development of mullite clinker.

Sintering and synthesizing mullite is generally carried out at 1650-1700°C. The main process factors affecting the synthesis of mullite by sintering method are the purity of raw materials, the fineness of raw materials and the calcination temperature. The sintering and synthesis of mullite mainly depends on the solid phase reaction between alumina and silica, so increasing the dispersion of raw materials will accelerate the process of solid phase reaction. Thorough mixing and fine grinding of raw materials is an important process condition to promote the solid phase reaction of synthesizing mullite to proceed fully.

Mullite generally starts to form at 1200°C and ends at 1650°C. At this time, it is microcrystalline. When the temperature exceeds 1700°C, the crystal phase is good. It can be seen that the combustion temperature directly affects the formation of mullite and the development of crystals. Therefore, heating to a certain temperature and extending a certain holding time are necessary conditions for the synthesis of mullite.

The purity requirements of the raw materials used in the synthesis of mullite are very strict, and a small number of impurities will reduce the content of mullite. However, in industrial production, it is inevitable to bring in impurities, mainly Fe2O3, TiO2, CaO, MgO, Na2O, K2O, etc. Among them, Na2O and K2O are the most harmful, they will reduce the formation of mullite and cause a large amount of the glass phase is produced, reducing the mullite content. Fe2O3 will delay the mullitization process and increase the number of glassy phases.

1.2 Sintered mullite features:

Sintered mullite has the advantages of uniform expansion, thermal shock stability, high load softening point, low high temperature creep value, high hardness, and good chemical corrosion resistance.

1.3 Sintered mullite application

Sintered mullite bricks are widely used in glass furnaces, hot blast stove and etc.

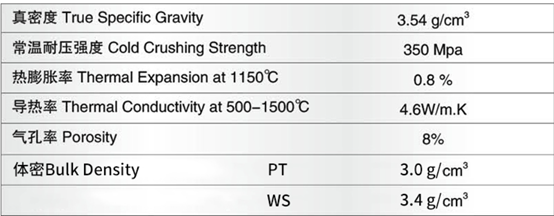

2. Fuse mullite bricks

2.1 Production technology

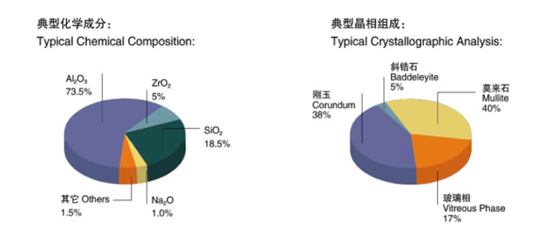

The raw material combination of fused mullite is industrial alumina, high-purity silica, alumina rock, etc. The Al2O3/SiO2 ratio of the ingredients determines the mineral phase of the fused mullite and the crystal shape of the mullite. Fused mullite is produced by melt crystallization, and its process is very similar to the cooling crystallization process of the Al2O3,-SiO2, phase diagram.

Firstly, crush massive raw materials such as silica and alumina rock clay to within 1.5m, and mix them with other powdery materials in a mixer. Spread a layer of mixed material on the bottom of the electric furnace, and use charcoal or electrode scraps as the arc starting material (when smelting high-purity mullite, the impurity content of the arc starting material should be lowered, and it should be laid in a star or triangle shape under the electrode. Lower the electrode to start. When part of the ingredients are melted and the current is stable above a certain value, gradually add materials from the periphery. The fused mullite solution has high viscosity and low conductivity. Pay attention to current changes during operation to avoid arc break.

When melting mullite, the atmosphere in the furnace should be in a reducing state. Because the raw materials contain impurities such as Fe,0, Ti02, R20, etc., especially when using alumina as raw materials, there are more impurities, and they need to be removed by reduction. At lower temperatures, the aforementioned impurity oxides are stable. At higher temperatures, the stability of CO exceeds that of the individual oxides, resulting in the reduction of the oxides to the corresponding metals by CO. The melting temperature of fused mullite is between 1850 and 2042°, and Fe0, FerO, and TiO2 are all easily reduced.

2.2 fuse mullite features

The quality of fused mullite raw material is higher than that of sintered mullite. The apparent porosity is lower than that of sintered mullite, which can prevent external substances from intruding into the material to a greater extent; with large crystals and many grain boundaries, its corrosion resistance, heat resistance, and creep resistance are all significantly improved. Widely used in environments requiring higher heat resistance.

2.3 Application

It is mainly used in parts that need to use wear-resistant and high-temperature-resistant materials, such as slide rail bricks of metallurgical pusher heating furnaces, or tapping platforms (tapping spouts) of walking heating furnaces that use tapping platforms (tapping troughs) for tapping steel channels), and the lining of waste incinerators.

Where can you buy the high-quality mullite bricks?

Zhengzhou SNR Refractory Co., Ltd (SNR) is a professional fuse cast refractories manufacturer in China for 30 years. We export refractories to 30 countries.

Whatsapp:0086-182 0397 6036,

Email:davis@snrefractory.com.