1. Alumina Bubble Brick Brief Introduction

Alumina bubble ball bricks are made of alumina bubble balls and alumina powder as the main raw materials, combined with other binders, and fired at a high temperature of 1750 degrees. It belongs to a kind of ultra-high temperature material energy-saving insulation material.

2. Alumina Bubble Brick Production Process

Before sintering, alumina bubble ball should be prepared first, and then alumina bubble ball bricks should be prepared. The preparation of alumina hollow spheres (bubble ball) is made of industrial alumina as raw material, which is melted by electric melting method and then sprayed.

After adding industrial alumina powder into the molten pool, it can be powered and melted. When the temperature of the molten liquid reaches or exceeds 2200 ° C, the molten liquid will roll, that is, the furnace body will be tilted to make the molten liquid flow out; at the same time, the compressed air will be used to blow the molten liquid. Due to the viscosity and surface tension of the melt, the melt forms hollow balls wrapped in air during the injection and condensation process, which are collected and screened and stored in different particles for later use.

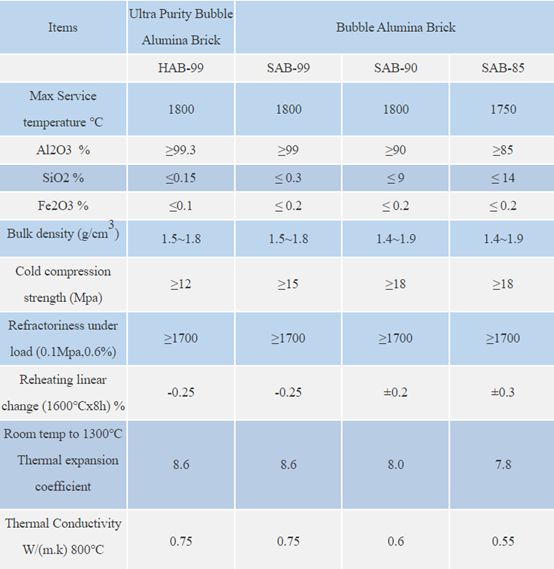

3. Alumina Bubble Brick Technical Specification

4. Alumina Bubble Brick Advantages:

1. High operating temperature: up to 1750 degrees or more, good thermal stability. The change rate of the reburning line is small, and it can be used for a longer period of time.

2. Optimize the structure and reduce the weight of the furnace body: now the high temperature resistant materials are all heavy bricks with a volume density of 2.6-3.0g/cm, while the alumina hollow ball bricks are only 1.1~1.5g/cm, the same volume of one cubic meter, The use of alumina hollow ball bricks can reduce the weight of 1.1-1.9 tons.

3. Saving materials: to achieve the same service temperature, the price of heavy bricks is equivalent to that of alumina hollow ball bricks, and considerable insulation layer refractory materials are also required. If alumina hollow ball bricks are used, 1.1-1.9 tons of heavy bricks can be saved per cubic meter, and 80% of refractory insulation materials can be saved.

4.Energy saving: Alumina hollow spheres have obvious thermal insulation properties and low thermal conductivity, which can have a good thermal insulation effect, reduce heat dissipation, and improve thermal efficiency, thereby saving energy. The energy saving effect can reach more than 30%.

5.Alumina Bubble Brick Application:

Alumina bubble ball bricks are used as lining bricks for high-temperature industrial kilns below 1800 °C, such as high-temperature kiln lining bricks for glass furnace refractories, electronics, and ceramic industries; thermal insulation layers for high-temperature thermal equipment, such as petrochemical industries Insulation bricks for industrial gasification furnaces, gas-making furnaces, carbon black industrial reaction furnaces, and induction furnaces for metallurgical industries.

Application in the above fields can save energy by 20% to 30%. This kind of brick is used as the inner lining of high-temperature kiln, and the heating rate should not be too fast during baking, otherwise cracks will occur, which will reduce the strength and service life; Damaged by penetration of slag.

Where can you buy the high-quality alumina bubble bricks?

Zhengzhou SNR Refractory Co., Ltd (SNR) is a professional refractory materials manufacturer in China for 30 years. We export refractories to 30 countries for glass factories.

Whatsapp:0086-182 0397 6036,

Email:davis@snrefractory.com.