What are the raw materials for producing bonded refractory bricks in glass industry?

Refractory raw materials refer to the materials necessary for the production of refractory products. It is the basis for the production of refractory materials. Most of the refractory raw materials are natural minerals (such as refractory clay, high alumina, silica, chrome ore, magnesite, dolomite, forsterite, zircon, kyanite, sillimanite, andalusite, etc.), With the continuous improvement of the comprehensive performance requirements of refractory materials, more and more industrial raw materials and synthetic raw materials are used in the production of refractory materials (such as industrial alumina, synthetic mullite, artificial refractory fibers, artificial refractory hollow balls, etc.) . The quality and cost of refractory products depend to a large extent on the correct selection and rational use of raw materials.

Usually, refractory materials are divided into aluminum-silicon-based refractory materials (silicon, clay, high-alumina, etc.), alkaline refractory raw material, heat-insulating refractory materials and other refractory materials.

1. Silicon raw material

The main component in silica is SiO2, and the others are impurity components. There are two types of siliceous raw materials for refractory materials: crystalline silica and cemented silica.

| Technology | crystalline silica | cemented silica. | ||

| vein quartz | Quartzite | Quartz sandstone | chert rock | |

| Color | cream | gray,light gray | light yellow/light red | red-white, blue-white |

| Mineral | Mainly quartz, pure texture, with red and yellow-brown rust | Mainly quartz, some contain clay, mica, feldspar, chlorite, rutile, iron-containing minerals, etc. | Mainly quartz, a small amount of mica, feldspar, a small amount of siliceous cement | The matrix is chalcedony, which contains quartz grains, some with iron oxide |

| Chemical Composition | SiO2 99% | SiO2 > 98% | SiO2 > 96%, Al2O3 1-3% RO2 1-2% |

SiO2 > 96%, |

| Quartz grain | > 2mm | 0.15-0.25mm | 0.2-1 mm | 0.005-0.01 mm |

| Softening Property | SLOW | SLOW | Middle Speed | Fast |

Refractory clay is the main raw material for the production of aluminum silicate refractory materials. All kinds of hard clay, soft (semi-soft) clay and clay shale whose refractoriness is required to be higher than 1580°C are collectively referred to as refractory clay.

Natural refractory clay is usually composed of clay minerals mainly kaolinite (Al2O3 2SiO2 2H2O), that is, hydrous silicate as the main body, and mixed with free quartz, pyrite, rutile and organic matter. mixture. Most of this non-single mineral is a dispersion composed of particles with a diameter of less than 1.2 μm.

The refractory clay used in the refractory industry mainly falls into the following two categories.

① Hard clay is characterized by dense structure, high hardness, extremely fine particles, not easy to disperse when exposed to water, and low plasticity. These clays are often light gray, off-white or gray in appearance. Shell-shaped fracture, some surface has a slippery feeling, easy to weather and break into pieces.

② Soft (semi-soft) clay is often lumpy, with soft tissue and good plasticity. The color of this clay varies greatly due to the different types and contents of impurities. From gray, dark gray, until black; some are purple, reddish or white.

3. High aluminum raw material

3.1 Bauxite

Bauxite is the main raw material for the production of brown corundum, and high-alumina clinker with an Al2O3 content of 88% and 90% , which is the main raw material for sub-white corundum; alumina is used as raw material for the production of white corundum and dense corundum. Bauxite is also known as high alumina or bauxite, and the main minerals are diaspore (Al2O3 H2O) and gibbsite (Al2O33H2O).

3.2 Sintered corundum and fused corundum

The artificial production of corundum is made by melting industrial alumina or high alumina bauxite in an electric arc furnace. In addition, corundum tabular alumina can also be prepared by sintering. This method is still based on industrial alumina powder as the main raw material, which is obtained by calcination, fine grinding, balling and firing. This method is technically difficult to produce, but the product has high strength, strong corrosion resistance, and good thermal shock stability.

3.3. Mullite

Mullite is a refractory material mainly composed of 3Al2O3 2SiO2 crystal phase. Mullite is divided into two types: natural mullite and synthetic mullite. There are very few natural mullites, and artificial synthesis is generally used. Mullite is chemically stable and insoluble in hydrofluoric acid. It has good high-temperature mechanical and high-temperature thermal properties. Therefore, synthetic mullite and its products have high density and purity, high-temperature structural strength, low high-temperature creep rate, low thermal expansion rate, strong chemical corrosion resistance, and thermal shock resistance. etc.

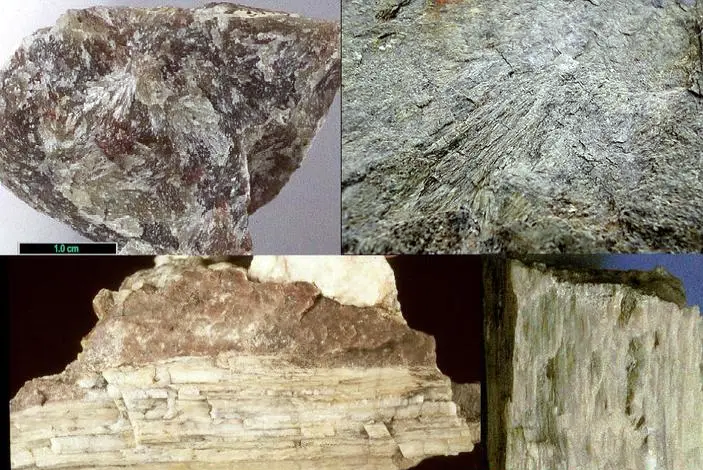

3.4 sillimanite group minerals

Sillimanite minerals include kyanite, andalusite, and sillimanite, commonly known as "three stones". The chemical composition of the three stones is the same, but the crystal structure is different, and they are homogeneous crystals. When heated to a high temperature, all of them are converted into mullite, and a small amount of molten SiO2 is generated, accompanied by volume expansion.

Due to the different sizes of the thermal expansion of the three stones, the degree of direct utilization is also different. Due to the small volume change of andalusite, whether it is used to make bricks or as an additive, raw materials are used directly. Sillimanite and kyanite are often added to the ingredients in the form of expansion agents, especially for amorphous refractory materials. And to make bricks, clinker must be calcined, especially kyanite must be calcined clinker.

4. Alkaline refractory raw material

4.1 Magnesium raw material

4.1.1 Magnesite

There are two main types of magnesite: crystalline magnesite and amorphous magnesite. Magnesite in my country is mainly distributed in Liaoning and Shandong provinces. The main impurity of magnesite is talc, and some magnesite contains higher CaO, and the second mineral is dolomite. According to the chemical composition, magnesite in my country can be classified into S, Ⅰ, Ⅱ, Ⅲ, Ⅳ five grades, only S grade and I grade are used for calcined brick magnesia.

High-purity magnesia is prepared by two-step flotation method and two-step calcination method. The high-purity magnesia prepared by this method can be used as raw material to develop a variety of high-performance refractory products.

4.1.2 Other Magnesium Minerals

Forsterite products in magnesia refractory materials, its main mineral composition is forsterite (2MgO SiO2) and periclase (MgO). This product is characterized by strong resistance to molten iron oxide and better thermal shock stability than ordinary magnesia bricks. The main raw materials for the production of such products are peridotite and serpentinite.

4.1.3 dolomite raw material

Dolomite is a refractory raw material mainly composed of double salt of magnesium carbonate (MgCO3) and calcium carbonate (CaCO3). Its chemical formula is CaMg(CO3)2 or MgCO3 CaCO3, and its theoretical composition is CaO3 0.41%, MgO2 1.87%, CO2 47. 72%. CaO/MgO = 1.39, hardness 3.54.

5.Raw materials for zirconium products

5.1 Zircon

The theoretical composition of zircon is ZrO2 67.01%, SiO2 32.99%. It often contains TiCfe and other traces of rare earth oxides, which are radioactive to varying degrees due to the presence of these elements. Therefore, when using this raw material to produce products, necessary protective measures should be taken.

The thermal conductivity of zircon is low, 3.72W/(m.K) between 201000°C. The expansion coefficient of zircon is also lower than that of other crystal phases, which is 4.6X10-6 °C at 1000 °C, and the expansion coefficient of its single crystal in the two directions of vertical and parallel to the main axis (C axis) is quite different. . Zircon has high chemical inertness and is difficult to react with acid. It reacts with glass melt to a small extent, and it is often used as a refractory material in metallurgy and glass industry.

5.2 badley zircon

Natural baddeleyite (ZrO2) is often irregular block, black, brown, yellow or colorless. There are very few natural baddeleyite ore bodies in my country. ZrO2 used in industry is a chemical raw material, which is a white or slightly yellow powder obtained by chemical methods from zircon (ZrO2·SiO2).

Pure ZrO2 has three crystal forms under normal pressure: monoclinic phase, tetragonal phase and cubic phase from low temperature to high temperature.

Stable ZrO2, depending on its degree of stability, can be divided into partially stable ZrO2 and fully stable ZrO2. Due to the large thermal expansion coefficient of fully stable ZrO2, its thermal shock stability is not as good as that of partially stable ZrO2, so the latter It is often used as a toughening material for ceramics and refractory materials.

5.3 Zirconium corundum mullite

The original raw materials are industrial alumina, kaolin and zircon, which are finely ground and mixed evenly, pressed into balls by semi-dry method and calcined at 1700°C to make this material. Studies have shown that increasing the content of zircon will increase the sintering temperature, reduce the total shrinkage, and increase the closed pores. These reactions make sintered zirconium corundum mullite have higher density and strength and better thermal shock resistance.

6. Raw materials for chrome products

One of the main raw materials for the production of chrome (chrome bricks, chrome-magnesia bricks, magnesia-chrome bricks) refractories is chrome ore or chromite. Chromite is a mixture of minerals that, due to its highly fluctuating mineral composition, vary widely in chemical composition and physical properties. It is usually composed of gangue minerals with chromic grains. These gangue minerals are usually magnesia silicates such as serpentine, forsterite and olivine. In addition to Cr2O3, there are also Al2O3, Fe2O3 and MgO in chromite ore. Generally, chromite ore is often represented by (Mg, Fe) Cr2O3 due to the presence of magnesium and iron.

The above are commonly used refractory raw materials. With the innovation of refractory materials technology, there are more types of raw materials. Especially in recent years, due to a series of reasons such as environmental protection issues and raw ore resources, artificial synthetic materials with better performance have been continuously developed. More environmentally friendly recycled raw materials.

Where can you buy the high-quality refractories blocks?

Zhengzhou SNR Refractory Co., Ltd (SNR) is a professional refractory materials manufacturer in China for 30 years. We export refractories to 30 countries for glass factories.

Whatsapp:0086-182 0397 6036,

Email:davis@snrefractory.com.