What are the maintenance measures for the operation of the float glass melting furnace?

The glass melting furnace is the heart of the float glass production line. Its service life mainly depends on the degree of corrosion and burning damage of the furnace wall, furnace crown, and regenerator. The correct use of the furnace and the maintenance of key parts are essential to prolonging the furnace life.

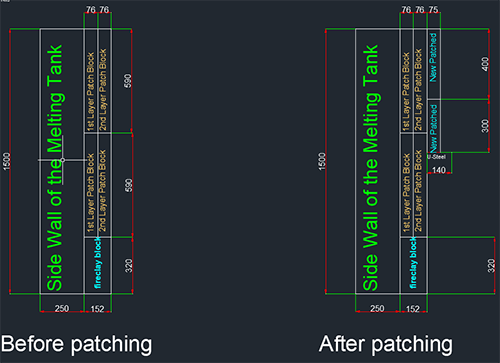

1. Side wall patching

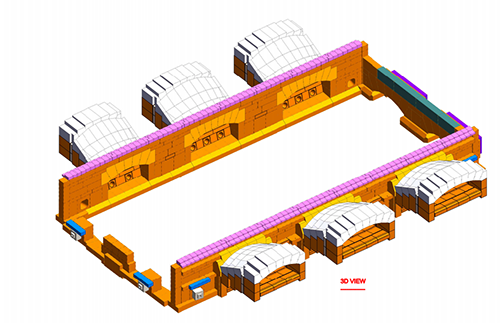

The thickness of the tank wall from the feeding end to the rear side was tested, and it was found that 3#~5# burner side wall on both sides were small. The furnace wall was severely eroded, with the thickness at its thinnest point being only 34mm. The pool wall of furnace A has been patched twice before, and it is planned to patch the pool wall bricks for the third time. According to the conditions of the patching bricks prepared, the patching thickness is 75mm and the height is 700mm, that is, 400mm+300mm (upper and lower layers). 140mm wide channel steel (U-Steel) is used for support, which leaves room for the fourth layer of patching. The specific plan is shown in Figure 1.

2. Ceramic welding repair

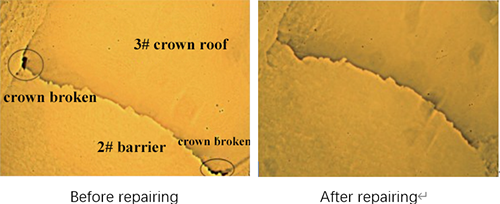

ceramics can be used as hot repair materials to adhere to damaged areas of refractory materials. The melting process will produce an exothermic reaction temperature that can reach 2200°C. Therefore, ceramic materials can be used to repair silica, alumina, AZS and magnesium oxide refractory materials. The repair and welding repair process does not require stopping the kiln, and has a relatively small impact on production. Kiln A regularly invites ceramic welding repair manufacturers to diagnose the severely corroded refractory material parts such as L's hanging wall, crown, chest wall, regenerator, etc., and perform ceramic welding repairs. When kiln A was in operation for 6 years, the hanging wall of feeding port L was repaired by welding.

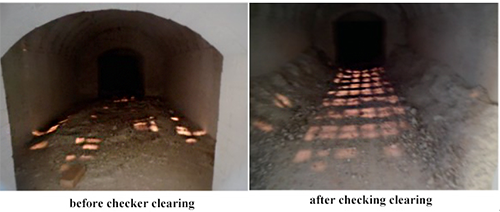

3.Regenerator clearing

After running for 8 years and 3 months, the L hanging wall nose area, the top of the regenerator of the 1# small furnace on the north side, the feet of the 3# small furnace regenerator on the south side, the feet of the 4# small furnace regenerator on the south side and The partition wall and the flat panel behind the 5# small furnace on the south side were welded and repaired. After welding repair, the ablated parts are repaired.

4.Add bubbler cooling system

Due to the long-term operation of the bubbler, the inner wall of the bubbler tube is severely corroded, and the return water temperature of some bubbler tubes exceeds the limit. Lowering the temperature of the circulating water in the cooling water tower cannot fundamentally eliminate the hidden danger of the bubbler being burned out.

For safety reasons, a bubbler cooling air system (see Figure 6) is added to prevent the glass liquid from flowing out and causing safety accidents.

.png)

We are dedicated to glass furnace design, refractory bricks research, development, manufacturing, furnace construction, innovation and upgrading for glass industry for 30 years.

whatsapp:+86-18203976036, email: davis@snrefractory.com