What are the Advantages and Disadvantages of the Fully Electric Furnace for Glass Melting?

Glass electric melting technology is the current melting process in the world, and it is a very effective way for glass manufacturers to improve product quality, reduce energy consumption, and fundamentally eliminate environmental pollution.

For small glass melting furnaces below 15t/d, in areas with sufficient electricity and moderate electricity prices, the comprehensive economic benefits of using electric melting technology to produce various glass products are ideal;

In regions with high electricity prices, it is also cost-effective for the production of colored glass, opal glass, borosilicate glass, lead glass, glass with high volatile components or special glass.

A. Electric Furnace Working Principle

Its main principle is to use electric energy as the heat source. Generally, a silicon carbide or molybdenum disilicate resistance heating element is installed on the side wall of the furnace for indirect resistance radiation heating. Some crucible furnaces for melting special glass use induction heating, relying on eddy currents generated by induction in the furnace and glass liquid for heating.

The pool furnace directly uses the molten glass in the furnace as a heating resistor, and multiple groups and multi-layer electrodes can be arranged at different depths of the molten glass to heat the molten glass, and the temperature system can be controlled by adjusting the power consumption. When using this method, the temperature of the space above the glass liquid level is very low (called cold furnace roof), so the energy is basically consumed in melting glass and heat dissipation on the furnace wall, and there is no loss of heat taken away by the flue gas and no environmental pollution impact when the flue gas is discharged, high heat utilization rate, and no need to set up combustion system and waste heat recovery system.

The electric furnace can be controlled automatically, with fewer management personnel and good working conditions, but consumes a lot of power resources. Suitable for melting refractory glass, volatile glass and dark glass.

B. Fully Electric Furnace Advantage

1. No exhaust gas, preventing air pollution. Since there is no combustion gas from the flame furnace kiln, all kinds of volatile substances are covered by the batch materials, and there is no problem of harmful smoke dispersion in the air.

2,Reduce the volatilization of volatile batch components. The table below shows that electric furnaces significantly reduce volatilization losses.

|

Proportion of reduction in volatilization loss unit % |

||

|

Volatile components |

Fuel Gas Furnace |

Fully Electric Furnace |

|

chlorine |

60-70 |

3 |

|

lead |

10 |

0.2 |

|

boron |

10-15 |

1 |

3,Furnace overhaul is faster. Overhaul of an electric furnace can be successfully completed within the 10-day deadline.

4,It can always maintain full load output during the whole furnace kiln period.

In fuel-heated or gas-heated furnaces, the ability to maintain heat input and glass output is often limited by deterioration of the combustion system.

In electric melting furnaces, the additional heat loss due to side walls can be quickly and easily compensated by increasing the electrical power input by increasing the voltage

5,The footprint is small.

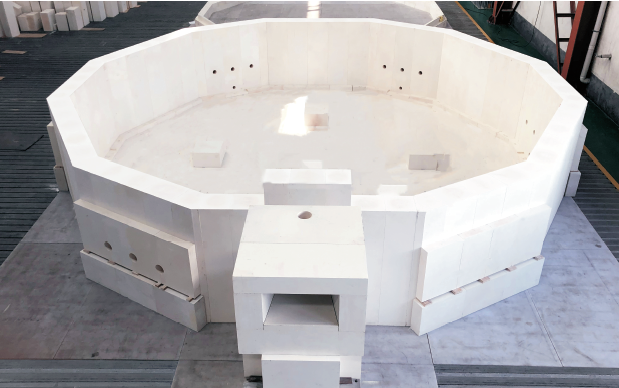

The electric melting furnace only includes the melting pool, the throat(liquid flow hole )and the ascending channel.

6,Heat loss is reduced and energy consumption is greatly reduced. The all-electric melting furnace realizes its melting by the conduction of the molten glass itself, and it is internally heated.

7,The finished glass is of good quality.

Since the melting is carried out inside the molten glass, the temperature difference along the depth of the melting pool is small.

The volatilization is less, and the glass composition is stable. The vertical melting reduces the stratification of high-lead glass.

All these guarantee the good uniformity and stability of the molten glass.

8,Clay brick construction requires less investment.

Auxiliary equipment is simple.

9,The all-electric melting furnace is easy to adjust and control, which has a wide operating range, and the thermal system is more stable than the pool tank furnace.

C. Fully Electric Glass Furnace Disadvantage

1,Electricity is still expensive in many areas.

2,The life of refractories is not long, and the life of refractories used in electric furnaces is not as long as that used in flame kilns furnace.

C. Conclusion

To sum up, all-electric melting furnaces can be considered when environmental protection requirements are strict, electricity prices are low, glass melting is difficult, glass quality requirements are high, and production scale is small.

.png)

Where can you buy the high-quality refractory bricks for electric furnace?

Zhengzhou SNR Refractory Co., Ltd (SNR) is a professional refractory materials manufacturer in China for 30 years. We export refractories to 30 countries for glass factories.

Whatsapp:0086-182 0397 6036,

Email:davis@snrefractory.com.