How many types of fuse cast AZS blocks and how to distinguish them?

Fused cast zirconia corundum bricks are also called fused cast AZS blocks.

According to the three chemical components of the Al2O3-ZrO2-SiO2, they are arranged in the order of their content. Al2O3 takes A, ZrO2 takes Z, and SiO2 takes S.

The main difference between fused cast AZS is the difference in zirconium content. According to the different zirconium content, they are divided into AZS33, AZS36, and AZS41, which represent 33%, 36%, and 41% zirconium content respectively.

1. Fused cast zirconia corundum block AZS33#:

The dense microstructure of AZS33# zirconium corundum bricks makes the bricks have good resistance to glass liquid erosion, and it is not easy to produce stones or other defects in the glass kiln. It is a widely used product in glass furnaces, and is mainly suitable for the upper structure, sidewall, and paving of the melting tank, and the forehearth, etc.

AZS33 is a widely used product in the AZS series of melting and casting products, and it has superior performance in preventing contamination of glass liquid. It is widely used in the tank wall, tank bottom, upper structure(superstructure) and feeding channel of glass furnace.

2. Fused zirconia corundum block AZS36#:

In addition to having the same eutectic as AZS33# fused zirconia corundum bricks, 36#AZS blocks have more chain-like zirconia crystals and lower glass phase content, so the corrosion resistance of AZS 36# is better. The performance is further enhanced, so it is suitable for areas with faster flow rate of molten glass or higher temperature.

AZS36 s is a product with excellent performance in the AZS series of melting and casting blocks It has high anti-glass erosion performance and low pollution characteristics. It is usually used in key parts such as the melting tank wall near the hot spot of glass furnace.

3. Fused zirconia corundum block AZS41#:

AZS41# fused zirconia corundum blocks not only have eutectics of silica and alumina, but also contain more uniformly distributed zirconia crystals. In the system of zirconia corundum blocks, their corrosion resistance is good. Therefore, key parts of the glass furnace are selected to balance the life of these parts with other parts.

AZS41 is a product with excellent performance in the cast AZS series products. It has extremely high resistance to glass liquid erosion and high glass phase exudation temperature, and has extremely low pollution to glass liquid.

It is widely used in key parts such as the tank wall at the hot spot of the glass furnace, doghouse corner, throat, weir, bubbling block at bottom of melting tank, and electrode block.

Where can you buy the high-quality fuse cast AZS blocks?

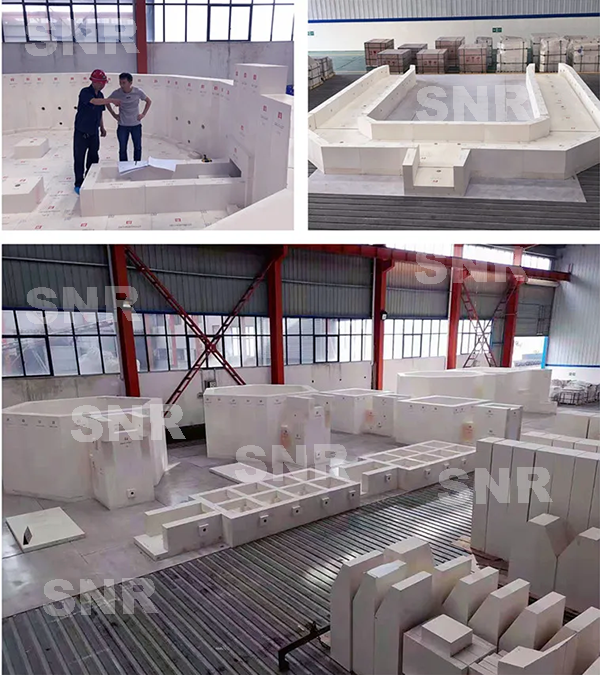

Zhengzhou SNR Refractory Co., Ltd (SNR) is a professional refractory materials manufacturer in China. We have over 30years experience in refractory bricks producing.

Whatsapp:0086-182 0397 6036,

Email:davis@snrefractory.com.