The glass furnace is the “heart” of glass production, and its stable operation is directly related to production efficiency and product quality. Water leakage is a frequent issue during furnace operation. Minor leakage may lead to furnace shutdown for maintenance, while severe leakage can trigger chain failures such as glass melt solidification and equipment damage. Among the many causes of water leakage, factors like furnace aging and improper operation have been widely recognized. However, as the key component directly exposed to high-temperature molten glass—fused cast AZS blocks—their quality issues and application deviations are often the root of hidden dangers. With excellent high-temperature resistance and corrosion resistance, fused cast AZS blocks are widely used in critical sealing areas such as the furnace tank bottom, sidewall, and throat. Therefore, solving water-leakage issues from the perspective of fused cast AZS blocks is essential for enhancing production safety.

The quality of fused cast AZS blocks is shaped throughout the entire production process, from raw material selection to process execution. Any oversight in any step may plant hidden risks that eventually lead to water leakage. Although comprehensive production standards for fused cast AZS blocks exist internationally and regionally, differences in standard implementation and process control among manufacturers result in inconsistent product stability, becoming a common material challenge faced by glass enterprises worldwide.

Some glass manufacturers exhibit cognitive biases during the acceptance of fused cast AZS blocks, placing excessive emphasis on surface smoothness while neglecting the inspection of key performance indicators. In reality, the surface layer of fused cast AZS blocks naturally undergoes segregation, enriching zirconia components. This “natural protective shell” is crucial for resisting erosion by molten glass. Although the surface may appear slightly rough, grinding it will directly destroy this protective layer, significantly reducing the brick’s corrosion resistance. As a result, the glass melt can more easily penetrate the brick during use, ultimately causing water leakage.Additionally, when acceptance personnel lack professional knowledge and focus on non-essential appearance details, substandard products—such as those with insufficient bulk density or excessive impurities—may pass inspection and enter the production process.

The hardware configuration and process control of fused cast AZS block production directly affect product quality. In terms of hardware, the equipment used for sand mold fabrication, the specifications of silica sand, the structure of insulation boxes, and the selection of insulation materials all influence the compactness of the sand mold and the quality of the casting. If the sand mold is loose, cavities are likely to form inside the brick after casting.

From the perspective of process control, raw material impurities, casting temperature, and feeding during the holding stage are the key aspects. Metal impurities in raw materials reduce the melting point of fused cast AZS blocks and increase the glassy phase content, resulting in a more porous structure. If the post-casting holding and feeding are insufficient, micro-pores will form inside the brick. These pores will gradually be infiltrated by molten glass at high temperatures, forming interconnected channels that eventually cause water leakage.

Furthermore, some manufacturers continue heating after secondary oxygen blowing during melting, which increases carbon penetration in the brick, further weakening its corrosion resistance.

The sealing safety of glass furnaces relies heavily on the service stability of fused cast AZS blocks. However, the working conditions of key regions such as the furnace tank bottom, sidewall, and throat differ significantly, subjecting fused cast AZS blocks to a combined effect of “mechanical abrasion–chemical corrosion–thermal stress damage.” The dominant damage mechanisms vary across different regions, and the final leakage paths also differ substantially. Conducting an in-depth analysis of the failure processes of fused cast AZS blocks in each region is the fundamental prerequisite for accurately preventing water leakage.

The furnace tank bottom serves as the load-bearing foundation of the furnace, supporting both the hydrostatic pressure of molten glass and high-temperature loads. It is typically paved with a uniform specification of fused-cast AZS 33 blocks. However, during actual operation, the erosion intensity varies across furnace-bottom regions due to factors such as batch charging, molten glass flow, and electric boosting. The erosion rates in different regions can differ by 3–5 times.If this differentiated erosion pattern is ignored and only a single material is used, the fused cast AZS blocks in high-erosion zones will fail prematurely, forming “localized penetration points.” High-temperature molten glass will then break through the insulation layer along these points, eventually causing bottom leakage. This “localized imbalance” is the defining feature of furnace-bottom leakage and must be addressed through targeted material selection and structural protection.

The fused cast AZS blocks at the doghouse tank bottom endure both mechanical impact and chemical corrosion. The high-frequency impact of falling batch materials generates micro-cracks in the zirconia-rich crystal layer on the brick surface. Metal impurities carried in the batch react with brick components at high temperatures, producing low-melting substances that infiltrate along micro-cracks to form “corrosion channels.”

Traditional fused cast AZS 33 blocks have a relatively thin zirconia protective layer and limited impact resistance. After a period of use, erosion pits easily form on the surface. When the remaining brick thickness drops below one-third of the design value, high-temperature molten glass rapidly penetrates the brick and attacks the underlying insulation bricks, whose temperature resistance is lower, ultimately causing bottom-seal failure and leakage.

Replacing this area with fused cast AZS 41 blocks significantly increases the protective-layer thickness and impact resistance. The reactivity between the main crystalline phase and metal impurities is also reduced. The service life can be extended by more than twofold, effectively preventing leakage risks.

The furnace bottom of bubbling zones faces an intensified erosion environment due to “high-temperature accumulation + flow-field disturbance.” The main damage path involves “thermal-stress cracking → glass

phase depletion → scouring-induced cavity expansion,” with strong concealment.

The primary heat source in this zone comes from molybdenum electrodes used for electric boosting at the furnace bottom. The electrode heats molten glass through Joule heating, and its surface temperature can reach 2000°C—far exceeding the furnace’s average operating temperature of 1550°C. This extreme temperature difference induces thermal-expansion imbalance in the fused cast AZS blocks: areas close to the electrode expand rapidly, while distant areas expand more slowly, generating tensile stress that produces radial thermal cracks.

Meanwhile, high temperatures accelerate the migration of the internal glassy phase in the fused cast AZS blocks. In fused cast AZS 33 blocks, the aluminosilicate glass phase liquefies at 2000°C and flows rapidly along thermal cracks, leading to structural porosity and a sharp reduction in abrasion resistance.More critically, molten glass near the electrode forms strong convection currents, producing a high-velocity flow field. This flow exerts continuous shear forces on the brick surface, stripping away already-weakened material and enlarging the thermal cracks, eventually forming an “erosion funnel” centered around the electrode hole.

Although electrode-hole bricks are typically made of higher-grade fused cast AZS 41 blocks, neighboring fused cast AZS 33 blocks are still heated through conduction, with surface temperatures exceeding 1800°C. Their glass phase depletion rate is 3–5 times higher than in other areas, making them weak links.Once the erosion funnel reaches two-thirds of the brick thickness, molten glass slowly infiltrates along the gap between the electrode and the brick. Early leakage appears as slight “sweating” around the electrode and is hard to detect. With continued infiltration, the insulation layer is gradually eroded, eventually causing sudden leakage.

To solve this, a “full-zone high-temperature protection system” must be established:

Replace all furnace-bottom bricks within 100 mm around the electrode hole with fused cast AZS 33 blocks, eliminating weak points caused by material differences.

Use a “stepped-joint” installation method to keep joint width ≤0.5 mm, minimizing infiltration channels.

For high-power furnaces, adopt ultra-high-zirconia bricks (>46% ZrO₂) as electrode-hole bricks. Their superior heat resistance reduces erosion rates around the electrode by more than 60%, fundamentally blocking erosion pathways.

The furnace-bottom electrode-hole region is the direct impact zone of extreme temperatures, with a damage mechanism dominated by “high-temperature melting–interface reactions.” The damage is concentrated at the interface between the electrode and the brick.

The massive heat released during electrode operation keeps the fused cast AZS block at the contact area above 1900°C—approaching the softening point of fused cast AZS 33 blocks—causing them to enter a semi-molten state with a severe loss in strength.Additionally, the molybdenum electrode reacts mildly with ZrO₂ in the brick at high temperature, forming Mo-Zr intermetallic compounds. These weaken the bonding strength at the interface, creating micro-gaps.

Even if the electrode-hole brick is fused cast AZS 41 block, adjacent fused cast AZS 33 blocks are still heated through conduction, reaching temperatures above 1700°C. At this temperature, the flexural strength of fused cast AZS 33 blocks drops from 25 MPa at room temperature to below 8 MPa, making them prone to breakage under molten glass pressure.

Once fractured, molten glass infiltrates rapidly along the electrode-hole gaps, forming a “circular leakage channel.” Early leakage appears as slight sweating around the electrode; if left unchecked, it progresses to noticeable leakage and may even cause electrode burnout due to insufficient cooling.

Therefore, bricks adjacent to the electrode hole must use the same material as the dedicated electrode-hole fused cast AZS 41 block—to form a complete high-temperature protective ring. High-temperature refractory mortar must be used during installation to reinforce sealing performance.

The throat serves as the only passage for molten glass to flow from the melting tank to the refining tank. At the entrance, molten glass forms a high-velocity jet due to “sectional contraction,” exerting strong “impact–abrasion” forces on the furnace-bottom bricks. The damage is primarily mechanical scouring with minor chemical corrosion.The cross-sectional area of the throat entrance is only 1/5–1/8 of the melting tank. Here, molten-glass flow velocity increases abruptly from 0.1 m/s to above 0.5 m/s, significantly boosting kinetic energy and causing concentrated scouring. This shear force strips zirconia crystals from the brick surface, roughening it and forming depressions.

Meanwhile, the intense flow promotes full contact between molten glass and air, creating a strong oxidizing atmosphere that accelerates the dissolution of Al₂O₃ in the bricks, further reducing surface hardness.Traditional fused cast AZS 33 blocks have a Mohs hardness of around 7.5. In this environment, surface wear rates can reach 0.5–1 mm per month. After 8–12 months, scouring pits deeper than 10 mm typically appear.

When pit depth reaches half the brick thickness, structural integrity is compromised, and molten glass penetrates into the insulation layer beneath. Because molten-glass flow in the throat is continuous and stable, once penetration occurs, the insulation layer can be completely eroded in a short time, causing noticeable leakage and even throat blockage, forcing furnace shutdown.

Replacing this region with fused cast AZS 41 blocks increases Mohs hardness to above 8.0, significantly enhancing abrasion resistance. The denser structure of fused cast AZS 41 blocks also reduces oxide dissolution rates by 40%, effectively resisting the combined effects of scouring and corrosion. In practice, the service life of fused cast AZS 41 blocks in throat-entrance furnace-bottom areas can reach over 30 months, aligning with the lifespan of throat structural components and providing coordinated protection that eliminates leakage hazards in this area.

The sidewall serves as the lateral protective barrier of the furnace, bearing the combined effects of molten-glass side pressure, high-temperature radiation, and flow scouring. Fused cast AZS blocks used in sidewalls fall into two categories: tilt-cast bricks and void-free bricks. Due to differences in manufacturing processes, their defect types differ significantly—tilt-cast bricks tend to develop internal voids due to deviations in process parameters, while void-free bricks often suffer structural looseness caused by insufficient thermal compensation during solidification. These internal defects are difficult to detect from appearance alone but eventually become “hidden channels” for leakage during operation.

At the same time, variations in molten-glass flow behavior across the furnace wall lead to blind spots when using traditional “localized key-area protection” strategies. Excessive erosion in non-key regions can also trigger leakage incidents.

The quality of tilt-cast sidewall block is extremely sensitive to process parameters. Deviations in casting angle, riser configuration, and melting procedures can all lead to internal looseness or void formation. These defects are unrecognizable from the exterior but serve as leakage paths during operation.Internal defects caused by process deviations follow clear patterns—once parameter deviations exceed critical thresholds, defect risks increase sharply.

If the tilt-casting angle is too small, molten material cannot flow smoothly to the far end of the mold, forming a structurally loose “retention zone.”

If the riser is positioned too far away or is undersized, shrinkage cavities cannot be adequately compensated, leading to honeycomb-like voids.

During melting, excessive heating after secondary oxygen blowing promotes zirconium carbide crystallization, which reduces flexural strength and accelerates erosion.

The core hazard of void-free sidewall blocks lies in the premature separation of the brick body from the riser during solidification, causing early termination of the compensation process. The riser’s key function is to supply molten material to the brick during the critical hours after casting. Better insulation enables longer compensation periods and results in higher density.

If the sand mold is placed improperly, the brick body may sink during cooling and separate from the riser, forming looseness or voids in the middle region.Brick sinking is caused by improper design of the casting-frame bottom. Traditional insulation-brick padding leaves a gap between the sand mold and the frame bottom, giving the brick space to sink. The improved solution is to thicken the insulation layer at the frame bottom and use high-temperature adhesives to ensure tight bonding between the sand mold and the frame, eliminating sinking gaps.

Additionally, poorly compacted insulating sand inside the insulation box causes rapid brick cooling and premature solidification of molten material, resulting in internal defects.

Traditional sidewall material allocation typically applies fused cast AZS 41 blocks only in visibly critical areas such as the doghouse corner and bubbling zones, while all other regions use fused cast AZS 33 blocks. This approach ignores “non-obvious high-erosion regions” created by molten-glass flow, resulting in frequent leakage in these overlooked zones.

In practice, molten-glass flow along the sidewall displays complex circulation patterns. Some non-key zones experience erosion equivalent to that in the designated key regions due to local flow disturbances:

Sidewall near the doghouse: Impact from falling batch generates strong vortices in molten glass. Vortex rotation speeds can reach 0.3 m/s, producing continuous shear forces that strip crystalline particles from the brick surface.

Opposite side of the doghouse: Molten-glass backflow generates high-speed streams that exert impact pressures up to 0.2 MPa, thinning the brick surface.

Both sides of the furnace breast wall: Overall circulation flow produces persistent frictional scouring. Although not intense, long-term action gradually erodes the bricks.

In these regions, fused cast AZS 33 blocks exhibit erosion rates of 0.3–0.5 mm/month. After 15–18 months, brick thickness typically falls below half of the design value, drastically reducing anti-penetration ability. Once micro-cracks form, molten glass rapidly infiltrates along them, causing furnace-wall leakage.

The solution is to optimize the material-allocation strategy by upgrading from “localized protection” to “full-area balanced protection.”

On top of the traditional use of fused cast AZS 41 blocks in key areas, all high-scouring regions—doghouse side, opposite side, and both sides of the breast wall—should be upgraded to fused cast AZS 41 block, forming a complete protective system.

Furthermore, according to erosion differences along the wall height, a segmented material configuration should be used:

♦ Lower sidewall (in direct contact with molten glass): fused cast AZS 41 block

♦ Upper sidewall (exposed only to radiant heat): fused cast AZS 33 block

This ensures optimal protection while maintaining cost efficiency.

The throat is the mandatory passage for molten glass in a glass furnace. The cover bricks and throat bricks are critical structural components whose quality directly determines sealing safety. Among them, internal cracks in the throat cover brick are the most concealed leakage hazard, originating from inadequate thermal-stress release after casting.

Thermal-stress release during casting follows natural laws. If casting temperature is insufficient or insulation is inadequate, this balance is disrupted, forming delayed internal cracking. These cracks result from differing cooling rates between the brick surface and interior. The surface contracts rapidly while the interior remains hot and expanded; when the induced tensile stress exceeds the brick’s tensile strength, microscopic cracks form.

These cracks are extremely short and closed at the time of unpacking and cannot be detected by appearance inspection. However, under the throat’s high-temperature, high-pressure environment, they extend progressively:

♦ High temperature softens the glassy phase around the crack.

♦ Pressure forces molten glass into the crack.

♦ Upon cooling, infiltrated glass solidifies and expands, enlarging the crack.

♦ Eventually, a fully penetrated channel forms.

The key to avoiding internal cracks is precise control of casting temperature and insulation. Different brick sizes require matching casting-temperature standards, and sufficient insulation time is necessary for complete thermal-stress release.

A simple appearance check can help: if the brick surface shows tortoise-shell-like yellow stripes, the internal stress has been fully released and the brick is safe to use.

To address leakage risks associated with fused cast AZS blocks, prevention strategies must be developed from three dimensions: manufacturing process, material allocation, and acceptance standards, thereby improving overall furnace-operation safety.

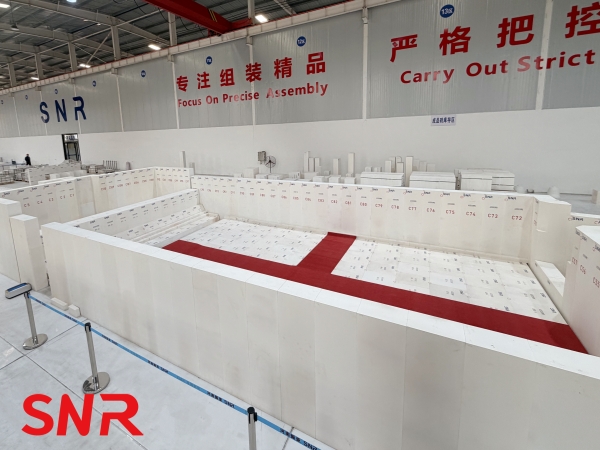

Manufacturers must establish full-process control systems, realizing standardized control from raw materials to finished products.

Raw materials: Ensure stable major components through professional testing, reduce metallic impurities through multi-stage iron removal, and monitor silica additions in real time to prevent excessive glass phase production.

Melting: Implement standardized procedures, precisely control temperature after secondary oxygen blowing, and avoid secondary overheating.

Casting and insulation systems:

♦ Tilt-casting should use CNC equipment to ensure stable casting angle.

♦ Use a “near-end + dual riser” configuration to ensure full compensation for large bricks.

♦ Void-free bricks should adopt integrated frame-bottom structures with vibration-compacted insulating sand for improved insulation.

Final inspection: All finished bricks must undergo ultrasonic testing to detect internal defects and ensure absence of voids or cracks.

A scientific material allocation strategy must follow the core principle of “operational-condition matching.” By considering the erosion intensity and mechanical characteristics of each furnace section, differentiated adaptation schemes can be formulated to balance “precise protection” and “cost optimization,” thereby avoiding leakage risks caused by material mismatches.

For the furnace tank bottom, a material strategy of “reinforced key areas + standard adaptation for regular areas” should be adopted. The four highly erosive zones—the charging port, both sides of the bubbling area, the surroundings of the electrode holes, and the throat inlet—must all use fused cast AZS 41 blocks. This grade contains 41% baddeleyite, with a crystallized baddeleyite layer twice as thick as that of fused cast AZS 33 blocks. Its impact resistance and chemical corrosion resistance are significantly enhanced, enabling it to withstand combined effects such as raw-material impact, high-temperature accumulation, and high-velocity scouring.

Within 100 mm around each electrode hole, a “stepped joint assembly” process must be applied: the joint width between fused cast AZS 41 blocks and special electrode-hole blocks should be controlled within 0.5 mm, and the joints must be filled with high-temperature refractory mortar (withstanding ≥1800°C), forming a sealed protection ring. For large furnaces with power ≥500 kW, the special electrode-hole blocks may be upgraded to ultra-zircon fused cast AZS blocks with 46% ZrO₂ to further enhance high-temperature performance.

The remaining regular areas of the furnace bottom continue to use fused cast AZS 33 blocks, which meet basic protection requirements while controlling material cost, achieving balanced overall erosion rates.

For the sidewalls, a material scheme of “full-area coverage + sectional optimization” is implemented, breaking the limitations of traditional “localized reinforcement.” While retaining the usual use of 41# materials at key nodes—such as doghouse corners and bubbling blocks—non-obvious high-erosion zones including the doghouse sides, the opposite wall, and both sides of the doghouse are also fully upgraded to fused cast AZS 41 blocks.

Sectional configuration is applied according to sidewall height:

♦The lower half (from the furnace bottom to 200 mm above the glass-melt level) is in direct contact with the melt and is subjected to the most severe scouring and erosion, so it must be entirely built with fused cast AZS 41 blocks.

♦ The upper half is exposed only to high-temperature radiation without direct scouring, so fused cast AZS 41 blocks are sufficient.

♦ For large furnaces with sidewall heights exceeding 3 m, an intermediate “transition layer” may be added using fused cast AZS 36 blocks , balancing protection and cost.

♦ As the core sealing region, the throat channel adopts an “all-41# material + specialized quality-control” strategy. The cover blocks and the main channel blocks should both use 41# fused-cast materials, and must follow stricter production standards—casting temperature no lower than 1820°C, with a holding time extended to over 3 hours to fully release thermal stress and prevent internal cracking defects.

Before installation, the cover blocks must undergo ultrasonic flaw detection and surface stress testing to ensure no micro-cracks or residual stress. During installation, a “dry-laying + gap filling” method is used: 1–2 mm expansion gaps are reserved between blocks and filled with high-temperature ceramic fiber rope, ensuring sealing performance while accommodating thermal expansion and contraction, thus preventing cracking and leakage caused by stress concentration.

Glass manufacturers must abandon the acceptance misconception of “emphasizing appearance while neglecting performance” and establish a scientific acceptance system oriented toward the core performance of fused cast AZS blocks. Through “professional training + standard implementation + process control,” they can ensure that only qualified products enter the production stage, thereby eliminating leakage risks from the very source of application.

Develop differentiated acceptance standards and clearly define the principle of “core indicators first.” Performance testing should focus on three key indicators: a bulk density ≥ 3.7 g/cm³, which directly reflects the compactness of the brick—insufficient density increases porosity and makes it easier for molten glass to penetrate; a room-temperature flexural strength ≥ 25 MPa to ensure that the brick does not fracture easily under the pressure of molten glass; and an apparent porosity ≤ 3% to reduce the risk of glass penetration into the brick interior. For each batch, five samples should be randomly selected. The bulk density should be measured using the drainage method, the flexural strength with the three-point bending method, and the apparent porosity with the mercury intrusion method. Only when all three indicators meet the standards can the product be deemed performance-qualified. Appearance inspection only requires the removal of surface sand and foreign matter; slight rough surfaces caused by natural segregation are acceptable. However, surface grinding is strictly prohibited in pursuit of smoothness—grinding destroys the zircon-enriched “natural protective shell,” reducing erosion resistance by more than 50%. (Accurate and complete translation.)

Strengthen the professional competence of acceptance personnel to eliminate “cognitive bias.” Organize the acceptance team to participate regularly in training on the performance mechanisms of fused cast AZS blocks, with a focus on the protective function of the zircon crystal layer, the applicable scenarios of different fused-cast brick materials, and methods of identifying defects, so as to avoid placing inspection emphasis on non-critical appearance details. After training, personnel must pass both theoretical and practical examinations, covering items such as “performance-index testing operations” and “correlating appearance defects with quality judgments.” Only those who pass the assessments may take their posts. At the same time, establish a “resident technical-expert” mechanism. For large-volume or special-specification fused cast AZS blocks, refractory-materials experts should be invited to participate in acceptance and provide professional support.

Build a process-control-based acceptance system to achieve “full traceability.” Before acceptance, verify product quality certification documents, including production batches, raw-material inspection reports, and melting-process parameter records, to ensure consistency with order requirements. During acceptance, keep detailed records such as sample numbers, test data, and appearance conditions, and form an acceptance report signed by both parties. For non-conforming products, immediately initiate the return or replacement process, define the responsibility boundaries, and include non-conformance information in the supplier evaluation system to push suppliers toward quality improvement. In addition, establish a usage-tracking archive for fused cast AZS blocks, documenting installation positions, service duration, and damage conditions for each batch, providing data support for future optimization of acceptance standards.

As the “protective barrier” of glass furnaces, the quality and scientific application of fused cast AZS blocks directly determine the effectiveness of leakage prevention. Detailed management across every stage—from manufacturing control to material allocation—can significantly reduce safety risks.

By standardizing production processes, optimizing material configurations, and establishing rational acceptance standards, the erosion and scouring resistance of fused cast AZS blocks can be significantly improved, fundamentally preventing leakage risks.

Moving forward, SNR will continue driving refined upgrades in fused cast AZS block technology and develop customized optimization strategies for different furnace-operation conditions, providing more reliable safety assurance for industrial production.If you have any needs, please contact me.