As an indispensable core equipment in the glass manufacturing industry, the importance of float glass furnaces is self-evident. The fused cast sidewall blocks of the furnace, as the key components supporting the entire structure, also play a great role. These blocks are not only directly exposed to extremely harsh working environments, including continuous high-temperature baking, erosion by complex chemical components in molten glass, and strong mechanical scouring generated by the flow of glass, but they also bear the important mission of maintaining the integrity of the furnace structure and ensuring the stability of glass quality.

As time goes by, the erosion problems of fused cast sidewall blocks will increase. The high-temperature environment will cause physical and chemical changes in the block material, such as crystal phase transition, volume expansion, or contraction, which will lead to a decrease in material strength and loose structure. At the same time, the active ingredients such as alkaline oxides and fluorides in the molten glass will react chemically with the block material to generate low-melting-point compounds. These compounds not only accelerate the erosion of the block but may also penetrate the glass, affecting the uniformity of the glass composition and the performance of the final product. In addition, the flow of molten glass, especially in dynamic processes such as rising bubbles and liquid level fluctuations, has a scouring effect on the sidewall blocks, aggravating the wear and erosion of the block surface. In severe cases, it may cause damage to the furnace structure and affect production safety.

Therefore, an in-depth understanding of the erosion mechanism of sidewall blocks and effective maintenance measures are of great significance to ensure the long-term safe operation of the furnace.

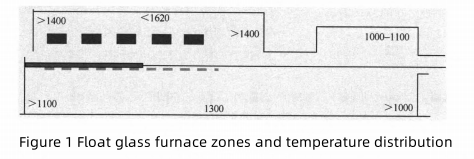

Float glass furnaces are necessary melting devices for the glass manufacturing industry. It uses advanced technologies such as oxygen combustion to release heat through fuel combustion and melt glass compounds to form glass liquid. The device has the characteristics of high efficiency, energy saving, and environmental protection, which can greatly improve productivity. At the same time, the structural design and waste heat utilization technology of float glass furnaces further optimize energy utilization and reduce pollutant emissions, which is of great significance for the sustainable development of the glass manufacturing industry. The float glass furnace belongs to the cross flame furnace, which is similar to the ordinary flat glass furnace. In structure, it can be divided into three parts: the melting part, the waist, and the working part. Typical float glass furnace partitions and temperatures are shown in Figure 1.

Fused cast sidewall blocks, as the key component in float glass furnaces, suffer the most severe flow erosion due to their direct exposure to high temperatures and highly corrosive glass solution. This erosion not only accelerates the loss of the sidewall blocks, but more importantly, causes a series of quality problems in the glass solution. Specifically, erosion causes the formation of air bubbles in the liquid glass, which appear as blemishes in the finished glass, reducing the transparency and aesthetics of the product. At the same time, erosion may also promote the formation of stones, that is, solid particles that are not completely melted are encased in the glass, affecting the uniformity and strength of the glass. In addition, continuous erosion will also leave deformation lines in the glass, making the product surface uneven phenomenon.

To improve the quality and production efficiency of glass products, the newly built float glass furnace needs to be extra careful in the selection of materials. The use of high quality, strong erosion resistance block becomes the first choice. These blocks should have the characteristics of being stable at high temperatures and not easily eroded by liquid glass. However, when it comes to balancing material costs with actual production benefits, most furnace manufacturers choose to use affordable, yet excellent, fused cast AZS blocks in the most eroded areas, such as the melting section and the neck area. Due to its excellent erosion resistance and long service life, this block is the preferred material in the construction of float glass furnaces.

The wear mechanism of fused cast sidewall block is a complicated process, which is mainly affected by both physical and chemical effects. In terms of physical effects, the wall of the glass melting furnace will repeatedly undergo the impact of acute cooling and heat during long-term operation, resulting in the structure of the fused cast AZS block being damaged, the surface cracks increasing, and the structure becoming loose. Under the scouring action of airflow, material, and glass liquid, the sidewall block is easy to crack and flake. In terms of chemical action, fused cast AZS blocks are subjected to high-temperature glass liquid for a long time, and the glass phase in the bricks gradually melts out. At the same time, the alkaline glass liquid containing Na2O will invade the block along the pores and cracks of the fused cast AZS block, and penetrate each other with the precipitated glass phase, resulting in intensified erosion behavior. With the erosion of the glass liquid to the depth, the skeleton minerals of the fused cast AZS blocks are gradually infiltrated and surrounded by the glass  liquid containing Na2O, finally lead to the complete disintegration of the brick structure.

liquid containing Na2O, finally lead to the complete disintegration of the brick structure.

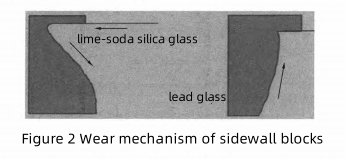

Ordinary float glass is generally calcium sodium silicon glass, and the specific gravity of glass is approximately 2.59 / cm3. The wear of fused cast sidewall blocks occurs on the surface in contact with the glass liquid, and the most eroded area is usually the position of the liquid level line. Under the double action of high temperature and liquid flow, the glass phase and corundum phase in the sidewall block will gradually peel off, leaving only the ZrO2 crystal phase. And because they are below the liquid level for years, these ZrO2 will gradually become spherical plagiorzircon. When the liquid level fluctuates greatly, the spherical clinozircon will flake off and fall into the glass, affecting the quality of the glass. The erosion of the fused cast AZS block was observed in the longitudinal direction. For calcium-sodium-silicon glass, due to the higher density of dissolved products, the erosion of the sidewall was heavier at the top and lighter at the bottom. Due to the different densities of lead glass, the erosion of the sidewall is opposite to that of calcium-sodium silicon glass, and the heaviest erosion occurs in the lower part of the sidewall. For the whole furnace, the sidewall block in the hot spot area of the flame zone has the most serious erosion due to the high temperature and the small viscosity of the glass liquid. Moreover, pulsed bubblers are usually used to produce colored glass, which further accelerates the erosion rate in this area. Because the temperature of the working part is lower than 1200 ° C, and the material is selected to be more resistant to erosion, the erosion will be very slight.

There are two ways to reduce the wear of sidewall blocks: air cooling and water cooling.

Air cooling is the most common form of cooling, especially when the sidewall blocks wear too thin, air cooling will significantly reduce the internal surface temperature of the sidewall blocks so that the erosion rate is greatly reduced.

Another common method is the installation of interstitial water packets, although it can effectively reduce the rate of sidewall wear. However, due to the significant increase in furnace energy consumption, and with a very large risk of water leakage, practical applications have become less and less.

Because of the low temperature, the flow of the sidewall in the doghouse area is not large, usually in a furnace period will not be washed. In the sidewall blocks in the doghouse area, the wear of the sidewall mainly occurs in the middle, which is related to the center clearance of the feeder. The larger the gap, the stronger the backflow, and the more severe the erosion.

The center clearance of the feeder varies from 140 to 500mm. For a feeder with a small gap, the sidewall erosion will be very small. If the large gap feeder is used, after more than 12 years of furnace age, it is necessary to closely observe the wear condition of the sidewall, and if necessary, it is necessary to extend the life of the furnace by paying water packs or tying blocks.

Since the sidewall block is above the feeder, in daily maintenance, special attention should be paid to maintaining the cleanliness of the sidewall block. Once a large amount of compound material is accumulated, it will cause a great risk when the feeder is pulled out.

In the erosion of sidewall blocks in the flame zone, the hot spot area is the most serious. In the absence of interstitial water packets, usually in the fourth or fifth year of the furnace, the first sidewall tie will be performed on the sidewall blocks in the area around the hot spot depending on the erosion of the sidewall blocks. For example, the furnace with 6 pairs of ports designed for 10 years is usually tied for the first time in the fifth year, and the area of tying blocks is 3# ~ 5# ports. For the port in the remaining flame zone, according to the actual wear situation, it can be considered to tie the remaining place of the flame zone around the 7th to 8th year. If you want to increase the furnace age to more than 10 years, you need to consider a second tying of the weak areas of the sidewall around the 9th year.

The entrance corner of the waist area is a weak point in the sidewall block, where erosion will be more severe as the area shrinks and the flow rate increases. Due to the special location of this area, there are a lot of various steel structures and supports, and daily inspection and maintenance are very difficult. At the beginning of production, the corner water tank is set up close to the sidewall, and the use of water cooling to protect the sidewall is a very good choice. If the card neck water pack is used, the two sides of the card neck water pack must be tight on both sides of the sidewall without leaving a gap. Otherwise, the gap on both sides will be washed more and more with the increase of furnace age.

Due to the selection of more erosion-resistant fused cast AZS blocks, the erosion of the working sidewall will be very slight. At the end of a furnace period (10 years), there is no need to replace the block as long as there is no problem with the inspection.

4 Summarize

As the most critical component of float glass furnace structure, the durability and stability of the sidewall block are directly related to the operation life of the whole furnace, that is the length of the furnace age. Sidewall blocks are exposed to extremely high temperatures and highly corrosive glass liquid environments for a long time and are under great pressure and challenge. Therefore, the selection of materials with better performance and stronger erosion resistance to manufacturing sidewall blocks is an important prerequisite for improving the overall performance of the furnace and extending the service life.

At the same time, only relying on high-quality materials is not enough, scientific maintenance is also crucial. Regular inspection, cleaning, and necessary repair work can detect and deal with potential hazards in a timely manner, preventing small problems from turning into major failures. Through a proper maintenance schedule, we can ensure that the sidewall blocks are kept in optimal working condition, thus ensuring the safe and efficient operation of the entire glass production line.

Henan SNR Refractory Co., Ltd(SNR) produces a variety of high-quality fused cast AZS blocks.If you have any needs, please contact us.

Web:www.snrefractory.com Email:moon@snrefractory.com

Web:www.snrefractory.com Email:moon@snrefractory.com