The glass furnace is the heart of a glass factory, and its operational safety is extremely important. As a large-scale thermal complex, the maximum flame temperature in the operation space of a furnace is generally above 1600℃, and the maximum temperature of the glass liquid needs to reach above 1450℃. During production, there are inevitably some phenomena of high-temperature flame damage to the refractory materials of the furnace body and erosion by high-temperature glass liquid, which will have an impact on the safe operation and service life of the furnace.

The burning and erosion phenomena of furnaces during operation can be controlled and reduced through professional hot-state maintenance. Common hot-state maintenance work includes tiling the sidewall, replacing the sidewall tiling, ceramic welding repair, replacing the port neck bricks, repairing the large arch and the rat holes in the regenerator, and repairing the inclined wall of the regenerator. The tuck stones of the port necks are the parts directly exposed to the impact of the flame. Although they all use the most resistant to burning damage and erosion, the fused cast AZS blocks, there is still a situation of gradual burning damage. As the furnace ages, when the burning damage reaches a certain extent, the lower protective chest wall support plate part will be exposed to the flame space, and even directly affected by the impact of the flame gas flow and burn. It brings considerable hidden dangers to the safe operation and the service life of the furnace.

In recent years, with the improvement of furnace maintenance technology, during the normal production and operation of furnaces, it has become a relatively mature furnace maintenance operation to replace the tuck stones of the port neck that have been burned out through hot-state maintenance. This can effectively protect the chest wall support plate from burning out and extend the safe service life of the furnace. There are also some furnaces where, due to factors such as poor quality of refractory materials or poor control of furnace operation flames, the tuck stones are burned out abnormally rapidly. Replacing some tuck stones in a hot state plays an even more important role.

1. The importance of tuck stone

(1) From the perspective of structural support, the tuck stone supports the structure of the port neck. As a flame jet channel, the port neck is heavy and has a complex working environment. The tuck stone acts like a solid foundation stone, evenly transferring the weight of the port neck to the furnace wall, preventing it from tilting or sinking, and ensuring the overall structural stability of the furnace.

(2) In terms of flame guidance and combustion optimization, tuck stones play a significant role. It can guide the direction of the flame. By rationally designing the shape and layout, and controlling the Angle and range of the flame spray, the flame can evenly cover the surface of the glass liquid, improve the heating efficiency, promote the thorough mixing and melting of the glass liquid, and reduce defects such as bubbles and streaks. Moreover, the hooked bricks help optimize the combustion process, promote the complete combustion of fuel, enhance combustion efficiency, reduce the direct impact of flames on the furnace wall, lower thermal stress, extend the service life of the furnace wall, and also reduce the emission of harmful gases, meeting the requirements of energy conservation, emission reduction, and environmental protection.

(3) The tuck stones also have the functions of fire resistance protection heat insulation and heat preservation. The temperature inside the glass furnace is high and corrosive. The tuck stones are made of high-purity refractory materials, such as fused zirconia corundum bricks, which can resist high temperatures and chemical erosion and protect the furnace structure. Meanwhile, it has heat insulation and heat preservation performance. The micro-porous structure and low thermal conductivity can reduce heat loss, improve the thermal efficiency of the furnace, lower energy consumption, and enhance the working environment.

(4) The condition of the tuck stone directly affects the service life of the furnace and the production quality. Its service life is related to the overall lifespan of the furnace. Selecting high-quality tuck stones and maintaining them properly can extend the service life and reduce the cost of equipment renewal. If there is a problem with the tuck stone, it will lead to uneven flame spraying and insufficient heating of the glass liquid, affecting the quality and uniformity of the glass melting and reducing the product qualification rate. Therefore, it is essential to attach great importance to the selection, installation, and maintenance of tuck stones.

2. Control the factors causing the burning damage of tuck stones

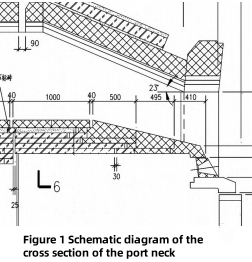

The horizontal flame regenerative chamber air-assisted combustion furnace is currently the most common furnace type, as well as some horseshoe flame air-assisted combustion furnaces. Most of them adopt bottom-burning spray guns, and the structure of their port neck is shown in Figures 1 and 2.

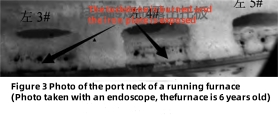

The furnace inspection after the cold repair of the furnace and the photos of the furnace inspection during production show that the burning damage of the port neck is relatively serious. In actual production, there have been cases where the tuck stones were severely burned or the chest wall support plates were burned and deformed after the hook heads fell off, with the support plates sinking and deforming by as much as 5mm. Figure 3 shows a photo of the tuck stones at the fire outlet inside the furnace that has been severely burned.

2.1 Factors Affecting the burning damage of the tuck stone at the port neck

Material factor

The material of the tuck stone is the key basis for controlling its burning loss. Refractoriness determines the stability of the block body in high-temperature environments. For instance, fused zirconia corundum blocks (AZS), with a refractoriness of over 1790℃, can better resist the high temperatures of furnaces without softening or deforming compared to ordinary clay bricks. The resistance to erosion affects the durability of the brick body when exposed to the erosion of molten materials, flying materials, and flame chemical components in the furnace. Fused cast AZS blocks containing high-purity zirconia and alumina have excellent resistance to the erosion of glass liquid and can effectively extend their service life. Thermal shock resistance is related to the integrity of the brick body during temperature fluctuations. Fused cast AZS blocks with special additives to optimize the crystal structure can maintain a good state in the furnace environment with large temperature fluctuations due to good thermal shock resistance, reduce cracks and spalling caused by temperature changes, and thereby lower the risk of burning damage.

Factors of furnace operation parameters

The operating parameters of the furnace have a significant impact on the burning loss of tuck stones. Excessively high flame temperature will directly accelerate the burning damage to the brick body. When the temperature exceeds the refractoriness of the tuck stone, the surface of the brick body will quickly soften and melt, forming depressions or holes. Therefore, it is crucial to reasonably control the flame temperature and avoid local overheating. The flame atmosphere can also alter the performance of the brick. In a reducing atmosphere, iron-containing bricks may be reduced, causing volume changes and cracking. The atmosphere needs to be adjusted according to the brick material and process requirements. In addition, the erosion caused by the flow of materials inside the furnace, such as the high-speed moving clinker particles in a cement rotary furnace, can wear down the surface of the brick body and reduce its strength. Measures such as optimizing the material distribution and lowering the flow rate can reduce erosion and control the burning loss.

Structural design factors

Whether the structural design of the tuck stone is reasonable or not is related to the degree of its burning loss. Unreasonable shape and size design can lead to stress concentration. For instance, stress concentration points are prone to occur at the corners of brick bodies, which are likely to crack under high temperatures and thermal stress. Adopting structures such as arc transitions can reduce stress concentration, and a reasonable size design can also ensure the stability of brick bodies during installation and use. The installation method is equally important. If it is not installed firmly, the bricks may shift or loosen during the operation of the furnace, increasing the gaps between the bricks and causing uneven heat conduction, which will accelerate the burning loss. Therefore, by adopting appropriate anchor fasteners and installation techniques to ensure a tight bond between the brick body and the furnace wall, the stability of the brick body can be enhanced and its service life prolonged.

Operational management factors

Operation management plays an important role in controlling the burning damage of tuck stones. If the heating and cooling rates of the furnace are too fast, it will cause significant thermal stress on the brick body, leading to cracking and burning damage. For instance, when starting or stopping the furnace, if the speed exceeds the brick body's tolerance, the internal temperature gradient will cause stress concentration, resulting in cracks. The speed must be strictly controlled by the regulations. Regular ash cleaning and maintenance can promptly remove accumulated ash and debris inside the furnace, preventing ash from affecting flame spread, and material flow, and causing corrosion and wear to the bricks. Formulating a reasonable ash cleaning cycle and maintenance plan can ensure the smooth operation of the furnace and help identify and address potential issues with the bricks. Meanwhile, by rationally arranging the production plan, maintaining a stable production load, and avoiding significant fluctuations in the operating parameters of the furnace, the risk of brick burning damage caused by unstable temperature and atmosphere inside the furnace due to excessive or frequent load fluctuations can be reduced.

3. Key points for controlling the hot-state replacement of the tuck stones at the port neck during production

During the production and operation of glass furnaces, the port neck is the part that suffers the most severe damage. Especially for regenerative combustion furnaces, the port neck is repeatedly impacted and changed by the circulating airflow from the upper and lower flames. The lower fire side is directly impacted by the hot air flow or even the flame. Therefore, the tuck stones at the port neck are often severely damaged. Under the tuck stones, the steel structure chest wall support plates are protected. When the tuck stones are burned and eroded to a certain extent, some of the chest wall support plates will be exposed to the flame space. The direct impact of the flame on the support plates will cause deformation and burning damage to the support plates, which will pose a hidden danger to the structural safety of the chest wall.

During the operation of the furnace, it is necessary to regularly inspect the burning damage of the furnace body. Methods such as observing with a fire mirror, measuring with a ruler, taking temperature, and taking photos with an endoscope should be adopted to assess the burning damage of the tuck stones and determine whether maintenance is needed and the timing of maintenance. Hot-state maintenance and replacement of the port neck tuck stones is a highly specialized thermal maintenance operation, which poses certain risks to the safety of the furnace and the safety of the operators. It requires a systematic plan and professional work.

The main steps of the operation process are as follows:

3.1 Hot repair plan formulation, personnel division of labor, and preparation of materials and tools

(1) Develop a hot repair plan. Professional furnace inspection and maintenance personnel use specialized furnace inspection tools such as endoscopes and cameras to inspect and take photos of the furnace's burning damage, determine the hot repair plan, and clarify which tuck stones to replace.

(2) The personnel division of labor is clear, including main operators, supporting and auxiliary personnel, and emergency safety supervisors.

(3) The corresponding thermal labor protection supplies are fully prepared, including emergency water guns, air guns, shovels, and steel for temporary reinforcement, etc.

(4) In terms of the preparation of hot repair bricks, the touchstones, port neck blocks, and spacer blocks should be replaced together. Considering the difficulty of the hot state replacement operation and the need to avoid cracking due to the rapid temperature rise during the hot state replacement of new bricks, the width dimension of the new tuck stones is generally set smaller.

3.2 Masonry of the brick-baking furnace: preheat the new bricks during the masonry process

According to the number of tuck stones and port neck blocks to be replaced, the masonry of the brick furnace is carried out, and the pre-heating is conducted by using the brick furnace. As shown in Figures 4 and 5, natural gas guns are generally used for heating.Before loading the new tuck stones and port neck blocks into the furnace, use a flashlight to inspect each brick material. Only when no problems are found can they be loaded into the furnace. To prevent the tuck stones from overheating and cracking, the port neck blocks and the spacer are installed on one side of the fire channel, while the tuck stones are placed on the side far from the fire channel. After the masonry of the brick furnace is completed, the bricks should be properly sealed and insulated after being placed in the furnace. The spray guns and monitoring thermocouples should be installed. The preferred order of fuel for heating is natural gas and liquefied gas. If diesel is used, attention should be paid to the uniformity of heating to avoid direct flame burning on the pre-heated bricks.

for heating.Before loading the new tuck stones and port neck blocks into the furnace, use a flashlight to inspect each brick material. Only when no problems are found can they be loaded into the furnace. To prevent the tuck stones from overheating and cracking, the port neck blocks and the spacer are installed on one side of the fire channel, while the tuck stones are placed on the side far from the fire channel. After the masonry of the brick furnace is completed, the bricks should be properly sealed and insulated after being placed in the furnace. The spray guns and monitoring thermocouples should be installed. The preferred order of fuel for heating is natural gas and liquefied gas. If diesel is used, attention should be paid to the uniformity of heating to avoid direct flame burning on the pre-heated bricks.

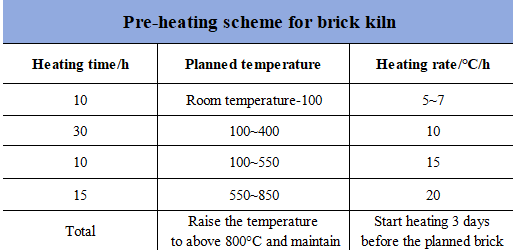

Formulate a detailed heating plan. According to the time of the hot repair plan, start heating the brick furnace three days in advance. Heat the brick materials to above 800℃ and keep them at that temperature for about 8 hours before starting the hot repair. The heating plan is shown in the following table. Refer to this heating rate. Generally, before heating up, new brick materials have been placed beside the melting furnace for 1 to 2 months to naturally dry the moisture. If the new brick materials have not been naturally baked by the edge of the furnace, the heating rate will be adjusted accordingly, and the heating rate in the low-temperature section will slow down.

The commonly used heating rate table is shown in Table 1.

3.3 Formulate the process adjustment plan during the hot repair period

To standardize the replacement of the tuck stones at the port neck, which may have a certain impact on the burner combustion of the port neck, a melting process adjustment plan needs to be formulated, along with detailed operation plans and emergency response plans. This is to avoid the arbitrariness of process operations during the replacement process and to prevent the impact on production caused by untimely adjustments to the pulling amount and combustion process. During the replacement of the tuck stones in the port neck, the main influences on the melting process are the adjustment of the spray gun, the drop in the furnace temperature, and the distance of the material mountain. Therefore, the main direction of process adjustment during the hot repair period is to timely adjust the fuel distribution, increase the fuel quantity of adjacent spray guns, and maintain the stability of temperature and material mountain.

3.4 Replace the tuck stones and adjust the port neck spray gun

When the hot repair work began, the molten chemical worker and the fitter removed and replaced the spray gun and gun frame corresponding to the position of the truck stone on the side of the fire tip. Then the furnace protection team began to remove the old port neck blocks, partition blocks, and tuck stones, and replace the tuck stones. During the removal process,  they paid attention to protecting the support plates and controlled the broken brick blocks to prevent them from falling into the glass liquid in the furnace. Note that the new tuck stone should be smaller in width than the old one. Start removing from one side of the port neck opening. After removing two tuck stones, install one new tuck stone in a hot state. Note that the new bricks should be kept warm in the port neck. When installing, use a special tool to quickly remove the new bricks and position them on the support plate. Brick removal and other operations should be carried out on the upper fireside as much as possible. When lowering the fire, insulation cotton should be used to block the fire. A certain reserve quantity of new bricks should be considered.

they paid attention to protecting the support plates and controlled the broken brick blocks to prevent them from falling into the glass liquid in the furnace. Note that the new tuck stone should be smaller in width than the old one. Start removing from one side of the port neck opening. After removing two tuck stones, install one new tuck stone in a hot state. Note that the new bricks should be kept warm in the port neck. When installing, use a special tool to quickly remove the new bricks and position them on the support plate. Brick removal and other operations should be carried out on the upper fireside as much as possible. When lowering the fire, insulation cotton should be used to block the fire. A certain reserve quantity of new bricks should be considered.

When removing bricks, try to pry them left and right as much as possible to reduce the number of direct strikes and prevent them from driving the iron support plate. During the process of making new bricks, the temperature of the brick furnace drops relatively quickly, so it is necessary to pay attention to the insulation of the brick materials. Before installing new tuck stones, carefully check for any cracking cracks. Bricks with cracking cracks are not allowed to be used.

3.5 Drawing volume and process control during hot repair

Before preparing to replace the tuck stones, comprehensively assess the current load and the clogging situation of the regenerator, and combine the designed melting rate and clarification rate to determine the reduction range of the pull-out volume before replacement (it can be reduced by 2% to 10% according to the assessment situation). During the replacement process, the pulling volume is dynamically controlled based on the working conditions inside the furnace. That is, according to the changes in the flame combustion state, temperature, material pile, and bubble boundary in the furnace at different construction stages, small up and down adjustments are made to ensure the stability of product quality and the control of heat consumption per unit. After the replacement is completed, restore the pulling amount before the replacement. The recovery amount should be ≤5t/d.

(1) Adjustment of the proportion of broken glass: Based on the inventory situation, under the premise that the quality of the purchased broken glass is under control, it can be increased by 2% to 4%. During the replacement process, temporary adjustments can be made as the situation requires. After the tuck stones are replaced, they can be gradually reduced and restored in combination with the drawing volume, the working conditions inside the furnace, and the quality of the glass.

(2) Fuel and air-fire volume adjustment: The fuel volume of the hot repair port neck should be appropriately distributed to adjacent port necks. The specific distribution should be based on the flame combustion situation, and the corresponding combustion-supporting air volume should be adjusted to ensure that the total fuel volume and total heat in the furnace do not change much and to ensure that the material flow and temperature are controllable. Fuel adjustment should ensure that the flame burns fully, stably, and with a certain degree of clarity. During the replacement process, closely monitor the material mountain, bubble boundary, and material deviation. When abnormalities occur, adjust the drawing amount or feeding coefficient accordingly. The adjustment of fuel and combustion-supporting air should be notified to the environmental protection department to ensure that the environmental protection import data is controllable.

(3) Feeding control: Before the official hot repair and replacement, the feeding machine is switched to a one-to-one control mode on the left and right respectively, which is convenient for the balance control of the material mountains on both sides during the replacement process.

(4) Furnace pressure control: It should be controlled within the normal furnace pressure index range as much as possible. During the replacement process, the non-heat change fluctuation should not exceed the normal furnace pressure set value by 5Pa. If there are any gaps in other parts of the furnace, they should be sealed in time and temporary sealing should be done well. The temperature of the arch top is controlled by setting temporary temperature indicators based on the working conditions inside the furnace to ensure the consistency and continuity of the operation of the teams.

3.6 Safety precautions

When baking bricks, strictly follow the temperature rise curve and arrange for dedicated personnel to be on duty 24 hours a day. Safety precautions should be taken in the passageway of the small stove and the area beneath it. During the hot repair period, the team should assign a dedicated person to be responsible for contacting the fire replacement. If necessary, manual fire replacement should be adopted to extend the burning time. The installation of the spray gun and the gun frame, as well as the new tuck stones, are all carried out on the fire root side. Before the replacement, the protection of the chest wall support plate should be done well. When cutting bricks with an oxygen-melting rod, the iron filings produced must not enter the furnace, and the old bricks should be removed as much as possible. Use special tools to clean the adhering substances and scrape them as clean as possible. During the replacement period, avoid knocking on the tuck stones to prevent debris from falling into the furnace and affecting the quality of the glass. Proper labor protection measures should be taken. When replacing the tuck stones, the operators need to wear labor protection equipment properly. It is necessary to prevent the on-site personnel from suffering from heatstroke, scalding, and other situations.

4. Conclusion

The tuck stone of the port neck is the part inside the furnace that is directly impacted by the flame. The tuck stone of the port neck is similar to the tongue of the early gas furnace, and its burning damage will directly affect the operating life of the furnace. By choosing better fused cast AZS blocks in terms of material, optimizing the structure to reduce stress cracks at the corners of the tuck stone head during the brick casting and forming process, and controlling the flame, flying materials, and temperature stability during the operation of the melting furnace, the burning damage of the tuck stone head can be effectively slowed down. Hot-state replacement of severely burned port neck tuck stones is a highly specialized thermal operation that has only been carried out in recent years, which can effectively extend the service life of glass-melting furnaces. A detailed replacement organization plan should be formulated, and a dedicated brick furnace should be built for pre-heating. The hot repair work should be carried out step by step, and a contingency plan for the melting process control during the hot repair period should be made. This can ensure the safe replacement of the port neck tuck stones and guarantee that the production during the hot repair period is not affected.

Among the many fused cast AZS block brands, SNR is undoubtedly your ideal choice. With its advanced production technology and strict quality control system, the SNR brand produces fused cast AZS blocks with excellent performance and reliable quality. Its fused cast AZS blocks are made of high-quality raw materials, smelted at high temperatures, and precisely formed, and have the advantages of high strength, high refractoriness, and strong corrosion resistance. In terms of structure, SNR fused cast AZS blocks are carefully designed to effectively reduce the occurrence of stress cracks and increase the service life of blocks. Whether it is a new furnace or furnace maintenance, choosing SNR fused cast AZS blocks can provide reliable protection for your furnace and help enterprises achieve efficient and stable production.

If you have any needs, please contact me.

Web:www.snrefractory.com

Email:moon@snrefractory.com