The glass furnace, often referred to as the "heart" of the glass industry, directly determines product quality, production costs, and the core competitiveness of an enterprise. The refractory materials that construct this "heart" serve as the cornerstone determining its service life, energy efficiency, and operational stability. Subjected to the relentless assault of internal temperatures exceeding 1600°C, highly corrosive molten glass, and alkaline vapors, the performance requirements of refractory materials extend far beyond mere "high-temperature resistance." They have become a pivotal technology with a decisive impact on the entire production process.

Currently, the glass manufacturing industry is confronting multiple pressures, including the need for energy conservation and consumption reduction, extension of furnace campaign life, enhancement of glass quality (particularly for high-end applications such as photovoltaic and electronic glass), and adaptation to environmentally friendly technologies like full-oxygen combustion. These challenges ultimately converge into a rigorous test of the performance limits of the furnace lining—the refractory materials. Traditional material systems can no longer fully meet the demands of this new era. The proactive evolution and innovation of refractory materials have thus become an imperative for driving progress in the glass industry.

This article will focus specifically on the domain of glass furnaces, providing an in-depth exploration of the core development trends exhibited by refractory materials in response to the aforementioned challenges. These trends primarily include high performance and high purity, as well as functionalization and structural design. The aim is to elucidate how these advancements provide essential support for constructing modern glass melting furnaces that are more durable, energy-efficient, and intelligent.

I. Core Driving Factors: Why Do Refractory Materials Need to Evolve Continuously?

The evolution of refractory materials is not spontaneous but is strongly driven by the core demands of the glass industry's development.

1. Economic Benefit Driver: Energy Saving, Consumption Reduction, and Cost Control

Energy constitutes the most significant cost factor in glass production. High-performance refractory materials directly reduce heat loss from the furnace through their excellent insulation properties. Their superior erosion resistance extends furnace campaign life from a few years to over a decade, significantly reducing the production cost per unit of product and avoiding massive losses associated with repair shutdowns.

2. Policy and Regulation Driver: Increasingly Stringent Environmental Requirements

Tightening global environmental policies impose strict limits on emissions such as nitrogen oxides and dust. This accelerates the adoption of low-carbon technologies like full-oxygen combustion. Consequently, a new generation of refractory materials must withstand the resulting higher temperatures and stronger alkali vapor erosion, becoming a critical enabler for compliance with environmental regulations.

3. Market Demand Driver: Trend Towards High-End Glass Products

High-end applications like electronic displays, photovoltaics, and pharmaceuticals impose extreme requirements on glass purity and homogeneity. Any erosion or reaction from refractories can introduce defects into the glass (e.g., bubbles, stones), rendering it substandard. Therefore, the high stability and cleanliness of refractory materials are prerequisites for ensuring the quality of high-end glass.

4.Production Mode Driver: High Efficiency and Smart Manufacturing

Modern glass production pursues ultimate operational efficiency, trending towards a "single campaign, long-term operation" model. This demands refractory materials possess ultra-high reliability and stability to support longer furnace campaigns, fewer unplanned shutdowns, and more predictable maintenance cycles, thereby laying the foundation for intelligent, continuous smart manufacturing.

II. Core Development Trends: The Direction of Technological Innovation in Refractory Materials

Based on the above drivers, the future development of refractory materials will focus on the following directions:

Trend 1: High Performance and High Purity

This is the most fundamental direction for refractories to meet industry challenges. The core lies in using high-purity raw materials and advanced manufacturing processes (e.g., high-pressure forming, high-temperature sintering) to minimize impurity content. This comprehensively enhances their resistance to molten glass and alkali vapor attack, high-temperature structural stability, and thermal shock resistance, meeting the needs of long campaign life and high-quality glass production.

Typical Representatives and Application Deepening:

1. Continuous Upgrading and Core Status of Fused Cast AZS Blocks

Fused Cast Alumina-Zirconia-Silica (AZS) blocks, due to their unique eutectic structure, form a high-viscosity zirconia-rich glassy phase at high temperatures, providing an exceptional barrier against molten glass. They remain the irreplaceable mainstream material for key parts of the glass furnace in contact with the melt (e.g., sidewalls, bottom, doghouse). Their value lies in direct contact integrity and acting as a safety barrier. Its application value is mainly reflected in:

Direct contact protection: These areas come into direct and continuous contact with high-temperature, highly corrosive molten glass, placing the most stringent demands on the material's corrosion resistance. The electric fusion process imparts a dense microstructure and exceptional strength to fused cast AZS blocks, effectively resisting erosion and corrosion.

Safety barrier: As the "inner lining" of the furnace, the integrity of fused cast AZS blocks is directly related to the furnace's safe operation and lifespan. Corrosion through these bricks will result in damage to the furnace and potentially a production halt.

New-generation AZS products, with ZrO₂ content increased from the traditional 33% to 40% or higher and optimized fusion casting for denser, more uniform structure, significantly extend service life under similar conditions, forming the cornerstone for furnace campaigns exceeding 10 years.

2.The expansion of sintered α-β/β-alumina bricks in superstructures

In glass furnace superstructures (such as arches and breastwall), materials are primarily subject to chemical attack from high-temperature alkali vapors and dust, rather than direct erosion from molten glass. In this area, high-purity sintered α-β/β-alumina bricks are becoming a powerful alternative or supplement to fused cast AZS blocks. They offer extremely low open porosity and higher high-temperature strength, and their stable crystalline structure offers exceptional resistance to alkali vapor attack. Their use effectively reduces the formation and fall of condensate on the furnace roof, preventing defects in the molten glass and is crucial for producing high-quality glass.

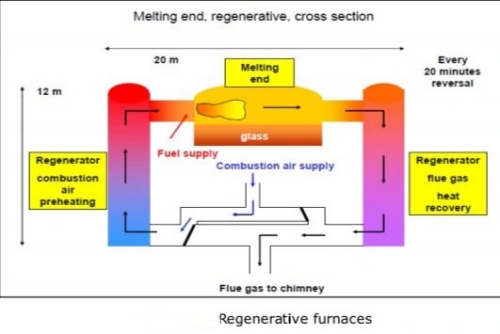

3. Environmental Substitution in Regenerators with High-Purity Magnesia and Spinel Bricks

In regenerator checkerworks, refractories endure severe temperature fluctuations and aggressive attack in a high-alkali environment. Traditional magnesia-chrome bricks pose environmental risks due to the potential formation of toxic, water-soluble hexavalent chromium (Cr⁶⁺). High-purity magnesia-alumina spinel bricks not only completely avoid chromium pollution but also demonstrate longer service life and better environmental characteristics than traditional materials due to their excellent thermal shock resistance and resistance to sulfate and alkali attack, making them the preferred choice for modern regenerators.

environment. Traditional magnesia-chrome bricks pose environmental risks due to the potential formation of toxic, water-soluble hexavalent chromium (Cr⁶⁺). High-purity magnesia-alumina spinel bricks not only completely avoid chromium pollution but also demonstrate longer service life and better environmental characteristics than traditional materials due to their excellent thermal shock resistance and resistance to sulfate and alkali attack, making them the preferred choice for modern regenerators.

Trend 2: Chrome-Free and Greener Solutions

Traditional magnesia-chrome bricks were once widely used in regenerators due to their excellent high-temperature performance. However, their critical flaw lies in containing hexavalent chromium (Cr⁶⁺), a substance that is highly toxic, water-soluble, and carcinogenic. Throughout its entire lifecycle—during production, use, and after disposal—it can cause severe pollution to soil and water bodies, directly harming the ecological environment and human health. Consequently, achieving "chrome-free" solutions has become an irreversible consensus and a clear direction for development in the global refractory industry.

The main current solutions include:

Magnesia-Alumina Spinel Bricks: As the most mature and widely adopted alternative, these bricks, through precise control of Al₂O₃ content and optimized microstructure, exhibit significantly improved high-temperature strength, slag resistance, and thermal shock resistance. They now meet the requirements for most middle and lower zones of regenerators.

Magnesia-Zirconia Bricks and Forsterite Bricks: Targeting specific temperature ranges and chemical erosion environments (e.g., acidic conditions) in regenerators, these specialized chrome-free materials offer more tailored solutions and serve as effective complements.

R&D of New-Generation Chrome-Free Basic Bricks: To pursue superior overall performance and more competitive costs, materials scientists are actively exploring novel chrome-free formulations based on various mineral systems (such as magnesia-calcia, magnesia-alumina-iron, etc.), continuously pushing the performance boundaries of chrome-free products.

Trend 3: Functionalization and Composite Structures

The operating conditions in modern glass furnaces are becoming increasingly harsh, and the temperature, chemical corrosion, and mechanical stress vary significantly across different sections (such as the crown, sidewalls, and throat). Consequently, a "one-size-fits-all" approach using generic refractory materials is no longer adequate to meet the demands for high efficiency and long service life. The key trend moving forward is toward functionalization and composite structures. This involves tailoring materials with specific properties to the service conditions of particular zones, or intelligently combining different materials in a composite design to achieve a synergistic "1+1>2" effect.

Application Examples:

1. Composite Structures for Sealing, Load-Bearing, and Insulation

In critical areas like the furnace crown, a functionally graded composite design is employed. The inner layer (hot face) uses dense, high-strength silica bricks or fused cast AZS blocks to ensure structural integrity and resist corrosion from high-temperature alkaline vapors. The outer layer (cold face) is built with multi-layer high-performance insulating bricks or nano-porous insulation panels, creating an effective thermal barrier. This structure not only significantly reduces the shell temperature and heat loss but also helps the inner bricks maintain a more stable temperature gradient, thereby extending their service life.

2. Localized Reinforcement for Enhanced Erosion Resistance in Key Areas

For the most severely eroded "bottleneck" areas, such as the throat and electrode blocks in the glass tank, various localized functional reinforcement techniques are used in addition to selecting high-quality fused cast refractories. Examples include inlaying plates made of precious metals (like platinum) or special alloys into the hot face of the lining, creating a physical barrier utilizing their superior corrosion resistance. Alternatively, forced air or water cooling systems can be designed outside the lining. By actively cooling the area, a protective, highly viscous layer of solidified glass forms on the brick surface in contact with the melt, dramatically reducing the erosion rate, protecting the main structure, and thereby extending the overall furnace campaign.

Trend 4: Intelligent Design and Smart Manufacturing

The refractory industry is transitioning from "experience-driven" to "data and model-driven."

Computer-Aided Design (CAD/CAE): In the R&D phase, using tools like molecular dynamics simulation and Finite Element Analysis (FEA) to model the interface reactions between glass melt and refractories, as well as thermal stress distribution, allows predicting material performance at the laboratory stage, accelerating the development of new formulations.

Application in Furnace Design: Using Computational Fluid Dynamics (CFD) and thermal simulation software to accurately model the flame space, glass melt flow, and temperature fields within the furnace provides a scientific basis for selecting the most suitable refractory material for each part, achieving "precise matching" and avoiding over- or under-engineering.

Smart Manufacturing Processes: Employing automated production lines, robotics, and AI-based quality inspection systems during manufacturing ensures high consistency in product dimensional accuracy, chemical composition, and sintering processes, greatly enhancing batch-to-batch stability and reliability of refractory bricks.

Trend 5: Long Service Life and Full Lifecycle Management

Glass manufacturers are no longer just buying "refractory bricks" but "solutions" and "guaranteed services." The role of refractory suppliers is evolving into that of service providers.

Ultra-Long Life Design: Integrating all the aforementioned technologies aims to push the service life of refractories in key areas to the limit. For example, the design life of photovoltaic glass furnaces is commonly required to exceed 10 years.

Predictive Maintenance and Expert Systems: Suppliers utilize sensors and data analysis to offer customers remote monitoring and diagnostic services for furnace operating conditions, predicting the erosion state of refractories, and planning optimal repair windows. This shifts the paradigm from "reactive repair" to "predictive maintenance," maximizing customer benefits.

III. Future Outlook

The future glass furnace will be a more efficient, clean, and intelligent ecosystem. Refractory materials, as its cornerstone, will continue to evolve towards ultra-high performance, environmental friendliness, and intelligent integration. We may witness:

Breakthroughs in New Materials: Such as the application of non-oxide composite materials (e.g., silicon nitride-bonded silicon carbide) in specific areas.

Deep Integration with Smart Manufacturing: "Smart refractory bricks" with embedded sensors transmitting real-time temperature and erosion data, becoming part of the Industrial Internet of Things (IIoT).

Full Lifecycle Carbon Neutrality: Carbon footprint management across the entire process, from raw material extraction and production to use and recycling, will become a new evaluation criterion.

Conclusion

The development of refractory materials for glass furnaces is a silent yet intense technological competition. It embodies the culmination of cutting-edge achievements in materials science, thermal engineering, and digital technology. Each material innovation propels the glass industry a significant step forward towards greater energy efficiency, environmental friendliness, and higher productivity. For glass manufacturers, closely monitoring and actively adopting these new refractory materials and solutions is not only a wise strategy for enhancing competitiveness and reducing costs but also an inevitable choice for fulfilling social responsibility and achieving green, sustainable development. The guardians of this "glass heart" are becoming increasingly powerful and intelligent.

Among the many industry-leading refractory suppliers, I highly recommend the SNR fused refractory brand. SNR fused cast AZS blocks, particularly its high-end AZS series, are renowned for their exceptional purity, superior corrosion resistance, and exceptional thermal stability. They are widely used in key components of various high-end glass furnaces. Choosing SNR means choosing proven reliability and durability for your furnace. This not only effectively extends furnace life and improves glass quality, but also provides a solid foundation for your company's strategic goals of cost reduction, efficiency improvement, and green production. In the pursuit of exceptional performance, SNR is undoubtedly your trusted partner.

Henan SNR Refractory Co., Ltd (SNR) focuses on producing high quality refractory materials.If you have any needs, please contact me.