Container glass is widely used in the food, beverage, pharmaceutical, and other industries and is an important material in packaging. The development of production technology is crucial for improving the quality of container glass, reducing costs, and enhancing production efficiency. Furnaces are the core equipment for container glass production, and all-electric melting technology is an advanced method that uses electrical energy as the heat source to achieve glass melting. Compared with traditional flame melting technology, it has advantages such as higher energy efficiency, lower environmental pollution, and better molten glass quality. Traditional furnaces have certain limitations in terms of energy consumption and environmental impact. As a new type of furnace technology, all-electric glass melting furnace bring new opportunities and transformation to container glass production. However, as a continuously developing technology, fully electric melting still faces a series of challenges during practical application that need to be carefully studied and addressed.

1. Working Principle of All-Electric Glass Melting Furnaces

All-electric glass melting furnace operate based on the principle of electric melting. Special electrode structures are installed inside the furnace; when alternating current passes through these electrodes, an alternating electric field is generated in the molten glass. Molten glass has a certain conductivity, and under the alternating electric field, the ions inside move directional and interact, producing Joule heat, which heats and melts the glass. This heating method is fundamentally different from traditional flame heating and enables precise control of molten glass heating.

The high-temperature melting of glass batch in all-electric glass melting furnace relies on ionic conduction heating. Monovalent metal ions such as potassium and sodium in the glass composition provide conductivity. Its conduction mechanism differs from metallic conduction, characterized by increased conductivity with rising molten temperature. The relationship between electrical resistance and molten glass temperature has the following features:① All glass components show negative resistance characteristics upon melting with respect to temperature.

② Due to different glass compositions, the electrical resistivity of molten glass varies greatly, and the slope of resistivity versus temperature differs.At low temperatures, glass is an insulator; at high melting temperatures, it becomes conductive due to alkali metal ions such as sodium and potassium. By arranging electrodes in different positions inside the furnace, the current passing through the molten glass generates heat via the Joule effect, enabling the transformation of the glass batch into molten glass. The entire process can be controlled by adjusting the input electrical power to regulate the melting temperature.

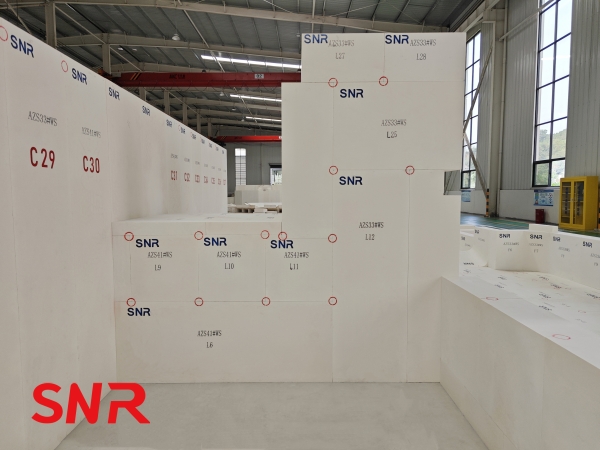

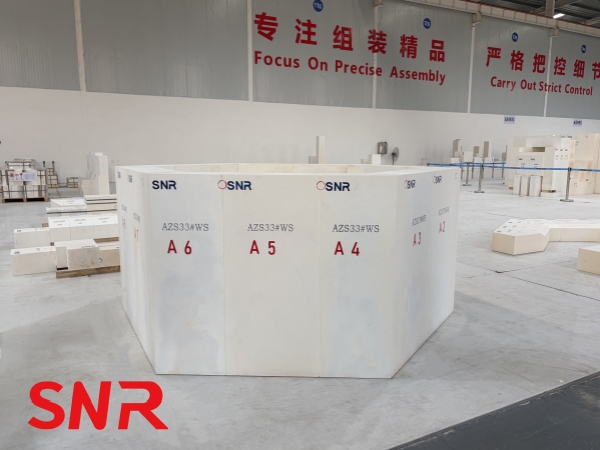

1.1 Fused Cast AZS Blocks

Fused cast AZS blocks are the core refractory materials used in all- electric melting furnaces. They are manufactured by melting high-purity raw materials at extremely high temperatures, followed by rapid cooling to form a dense, homogeneous structure with minimal porosity. These properties provide excellent resistance to chemical corrosion, thermal shock, and mechanical wear, which are critical under the extreme conditions of molten glass and strong electric fields.In all-electric glass melting furnace, fused cast AZS blocks serve several key functions:

Protect the furnace structure: Resist high temperatures and chemical attack from molten glass, including corrosive components such as fluorides and alkalis.

Enhance melting uniformity: Their homogeneous composition ensures even heat distribution in the molten glass, reducing defects such as bubbles, stones, and temperature gradients.

Extend furnace life: High thermal stability and low erosion rate prolong the service life of the furnace, lowering maintenance frequency and overall production cost.

The selection and quality of fused cast AZS blocks are crucial for achieving stable and high-quality container glass production, especially when producing milk-white glass or other specialty products that contain highly corrosive additives.

2. Advantages of All- electric Furnaces in Container Glass Production

2.1 Structural Features

(1) The electrode system is meticulously designed, requiring the use of special materials that are resistant to high temperatures and corrosion. The optimized arrangement of electrodes enables a uniform electric field distribution within the molten glass, ensuring even heating of the glass melt.

(2) It offers excellent thermal insulation, equipped with high-performance insulating materials that effectively reduce heat dissipation from the furnace surface.

(3) It achieves superior automation control, enabling real-time monitoring and adjustment of key parameters such as temperature and electric field strength inside the furnace. This facilitates precise control, ensuring that the glass melt undergoes melting and forming under optimal process conditions, thereby enhancing the stability of product quality.

2.2 Energy Efficiency

Traditional flame furnaces heat the glass surface, with a large portion of heat carried away by flue gas, resulting in low thermal efficiency. In all-electric glass melting furnace, heat is generated directly inside the molten glass, while the space above the molten glass is a “cold top” structure with a temperature below 150°C. Energy is primarily consumed in melting the glass and heating the sidewalls, with no heat loss due to flue gases. Direct heating of the molten glass significantly improves energy utilization, increasing thermal efficiency by 30–60% compared with traditional flame furnaces.

2.3 Environmental Friendliness

All-electric glass melting furnace have no combustion process, producing no nitrogen oxides, sulfur compounds, or dust, thereby reducing industrial emissions and improving the production environment. In particular, during the production of milk-white glass, fluoride volatilization decreases from 30–50% in traditional flame furnaces to 5–8% in all-electric glass melting furnace, greatly reducing environmental pollution and helping companies lower pollution control costs.

2.4 High Product Quality

Using all-electric glass melting furnace reduces molten glass contamination caused by fuel combustion. The uniform electric field ensures even heating throughout the molten glass, reducing temperature gradients. This helps lower internal stress, improve optical uniformity, and maintain consistent physical properties. Heating power can be quickly and accurately adjusted at different production stages, preventing instability due to temperature fluctuations and reducing defects such as bubbles and stones. Container glass produced in all-electric glass melting furnace exhibits high transparency, strong strength, and high product qualification and premium rates, meeting the demands of high-end packaging such as premium liquor bottles and cosmetics containers.

2.5 Small Footprint

The structure of all-electric glass melting furnace is simple, with vertical melting. The molten pool is deeper than that in traditional flame furnaces, eliminating the need for large combustion, waste heat recovery, and dust control systems, significantly reducing the required floor space.

3. Application of All-electric Glass Melting Furnace in Milk-White Glass Production

3.1 Development and Application of Milk-White Glass Furnaces

Milk-white glass is formed by introducing fluorides such as sodium fluorosilicate and fluorite, which cause the glass to gradually become opalescent during forming. In flame furnaces, fluoride easily volatilizes, affecting glass quality, causing raw material loss, and polluting the environment. All-electric glass melting furnace reduce pollution and improve environmental efficiency.

The selection of refractory materials directly affects melting efficiency and glass quality. High-quality fused cast AZS blocks, with low porosity, high corrosion resistance, and excellent thermal shock stability, can withstand high-temperature molten glass and fluoride corrosion, extending furnace service life. Additionally, their homogeneous structure ensures uniform temperature distribution, reducing defects like bubbles and stones, thereby improving transparency and physical properties of container glass.

3.2 Furnace Structure

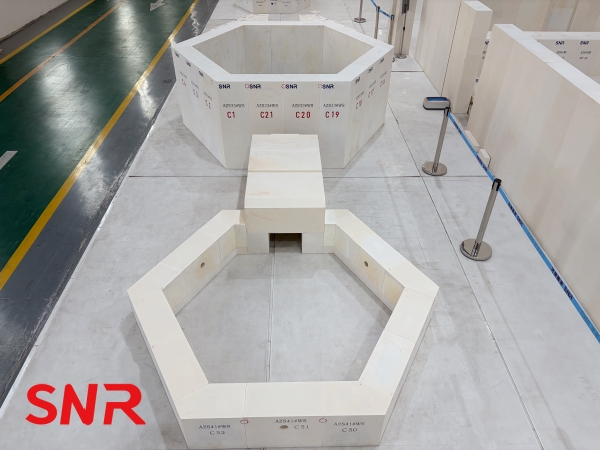

All-electric glass melting furnace are designed based on glass type, production scale, process requirements, and site conditions. Common structures include rectangular, hexagonal, or polygonal furnace bodies. Hexagonal or polygonal furnaces, though more complex and costly, reduce heat loss, minimize dead zones during melting, ensure uniform melting, and allow symmetrical electrode arrangement for balanced three-phase power supply.The furnace crown and batch charging differ from traditional flame furnaces. Glass batch must be evenly spread in thin layers on the molten glass surface from top to bottom, called the raw material layer. Mobile belt feeders evenly distribute the batch across the furnace, and the furnace crown may be flat. Refractory materials selection should focus on the crown and sidewalls:

1. During furnace heating, high temperatures are required, but during normal production, the crown temperature should be below 150°C, requiring refractory materials with good thermal shock resistance.

2. Flat-insert electrodes require drilled refractory bricks; the temperature near electrodes is relatively high. Milk-white glass contains fluorine, which aggressively corrodes the sidewalls. Convection caused by electrodes is several times faster than in flame furnaces, accelerating electrode-area refractory wear. Thus, sidewall refractory must have high temperature and corrosion resistance, typically high-zirconia fused cast AZS blocks.

3.3 Electrode Arrangement

Electrodes supply energy for glass melting and are evenly distributed around the furnace. Horizontal electrodes are inserted in three layers. Proper electrode power settings are required to maintain a cold top and achieve deep vertical melting. Other electrodes are arranged according to process requirements, mostly in flat-insert form.

Molybdenum electrodes have been widely used. Their production process is: molybdenum powder → pressing → sintering → pressure processing → inspection and delivery. Traditionally, molybdenum electrodes are arranged in “flat-insert” or “bottom-insert” modes. Horizontal electrodes are prone to bending under their own weight, limiting insertion depth; long electrodes risk breakage. Bottom-insert electrodes offer high melting efficiency and continuous feeding, but improper water jacket design and anti-oxidation measures can cause bottom brick corrosion and even leakage. Both flat and bottom insertions produce suboptimal temperature fields.

Top-insert electrodes, however, allow adjustment of installation position and electrode shape to optimize energy distribution, providing better melting conditions. They also facilitate replacement, maintenance, and extend furnace life. Top-insert electrodes are the future development trend.

4. Problems and Countermeasures in Container Glass Production Using All-electric Glass Melting Furnace

4.1 Electrode Lifespan

Electrode materials must meet multiple requirements: good conductivity, excellent high-temperature and corrosion resistance, and no contamination to molten glass. High-performance electrode materials are costly, while low-cost materials cannot sustain stable long-term operation. Electrodes are exposed to high temperatures, strong electric fields, and chemical corrosion from molten glass, such as alkali oxides and fluorides, which accelerate corrosion. High-temperature volatilization and wear are also significant. For example, molybdenum electrodes in high-alkali glass undergo oxidation and sulfuration, forming loose corrosion layers, reducing performance and lifespan. Frequent electrode replacement increases production costs and interrupts production, raising defect rates. Developing new electrode materials, optimizing electrode structure and installation, and minimizing contact with molten glass are necessary to extend service life.

4.2 Electrode Arrangement Issues

Electrode placement directly affects the electric field distribution. Improper spacing or shape design leads to uneven heating, causing local overheating or underheating, internal stresses, and reduced strength and optical quality. Uneven melting may also increase bubbles and stones, affecting glass appearance and internal quality. Electrode layout must be carefully studied to ensure uniform heating for high-quality container glass.

4.3 Power Supply Issues

All-electric glass melting furnace consume significant electricity. In regions with high electricity costs or unstable supply, production safety and stability are at risk, and costs rise. Voltage fluctuations or short outages can cause serious instability: high voltage may overheat electrodes or thin the batch layer, while low voltage reduces heating power and molten glass temperature. Sudden outages may solidify molten glass in the furnace, damaging equipment. Power supply stability must be carefully considered when designing furnaces.

4.4 Investment Cost Issues

All-electric glass melting furnace reduce environmental costs, but equipment development, manufacturing, and installation are expensive. Adopting all-electric melting technology often requires large-scale modification or replacement of existing flame furnace equipment, including feeding, forming, and control systems. Variations in equipment specifications make standardization difficult. However, widespread adoption and larger production scales can reduce equipment costs, and companies can plan investments considering long-term benefits.

4.5 Lack of Technical Talent

All-electric melting is a new technology, and skilled personnel are scarce. Lack of expertise in operation, maintenance, and management affects production stability. Companies need to collaborate with universities and research institutions to provide professional training programs. Internal technical training and knowledge sharing can cultivate personnel skilled in both glass production and All-electric melting technology.

4.6 Process Adaptability Issues

Different types of glass have varied chemical and physical properties, requiring adjustments in electric field strength, heating power, and melting time. Research on All-electric melting processes for different glass compositions is still insufficient, lacking mature standards and operating procedures. For some specialized glasses, All-electric melting may not produce quality products. Ongoing research and accumulation of technical experience are necessary for diverse glass production.

5. Conclusion

All-electric glass melting furnaces offer significant advantages in container glass production, with improvements in energy efficiency, product quality, and environmental performance compared to traditional furnaces. Widespread adoption requires addressing current challenges:

Electrodes: invest in new materials, optimize layout.

Power supply: ensure stability and efficiency.

Process: study glass-specific parameters and compatibility with existing equipment.

Talent: develop professional training programs.

Continuous technical improvement will promote high-efficiency, high-quality, and environmentally friendly container glass production, contributing to sustainable development in the packaging industry.

In summary, all-electric glass melting furnaces demonstrate clear advantages in container glass production. For more efficient and durable production, selecting high-quality fused cast AZS blocks is crucial.

Contact Information for Further Inquiries

For high-quality refractory materials, including fused cast AZS blocks suitable for all-electric glass melting furnaces, you may contact:

WhatsApp: +86 188 3808 9557

WhatsApp: +86 188 3808 9557

Email: moon@snrefractory.com